Lapping & Polishing Brass - Case Study

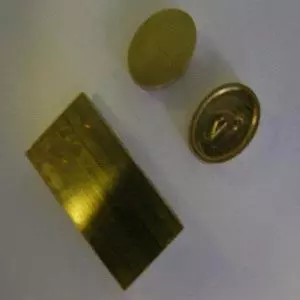

Test Requirements: Matt lap and mirror polish brass components

Component/Material: Oval & Rectangular Brass components

Stage 1 (Matt Lap) A cast iron plate on a Kemet 15 lapping machine with Kemox 0-800 Aluminium Oxide slurry and a run time of 5 minutes was used to give the components a flat matt finish prior to polishing.

Stage 2 (Mirror Polish) Finally an MRE cloth with COL-K and a run time of 20 minutes was used to mirror polish. This produced a blemish free mirror polish.

Before Lapping Brass

After Lapping Brass

| Process breakdown for lapping Brass | |||

|---|---|---|---|

| Stage | Plate/cloth type | Abrasive type/grade | Process time |

| 1 Lap | Cast Iron | Kemox 0-800 Aluminium Polishing Slurry | 5 minutes |

| 2 Polish | MRE polishing pad | COL-K (CMP Slurry) | 20 minutes |

Test Requirements: To lap and polish components. Ra < 0.2µm

Component/Material: Cast Iron body & Brass top plate.

Parts were run using a non-slip film on a pressure weight , which held 1 part in a control ring at once. The smallest part was hand lapped on the Kemet Iron plate for 15 seconds. Ra achieved on cast iron body: 0.0851 µm Ra achieved on brass plate: 0.0335 µm

| Process Breakdown | |||

|---|---|---|---|

| Stage | Plate/cloth type | Abrasive type/grade | Process time |

| Lap | Kemet Iron | Type K Standard Diamond slurry | 10-20 minutes, depending on damage |

Cast Iron body after lapping

Brass top plate after lapping

Brass component after lapping

Test Requirements: To improve flatness and surface finish on Brass plate

Component/Material: Brass plate, 69mm diameter

Machine Type: Kemet 24” diamond lapping/polishing machine

A total of 3 rings can be run on this machine. The parts were cleaned using Kemet C0-42 cleaning fluid. The Pressure weight used was a 15 inch machine pressure weight due to the size of the part (faced using an ant-slip membrane). A 24 inch machine could process a total of 9 parts per 5 minute cycle. Ra before - 0.1480 µm Ra after - 0.0332 µm Flatness before - Unreadable Flatness after - 1 light band (0.3 µm)

| Process Breakdown | |||

|---|---|---|---|

| Stage | Plate/cloth type | Abrasive type/grade | Process time |

| Lapping | Kemet Copper SP2 | Type O Standard Diamond slurry | 5 minutes |

After lapping Brass Plate