Colloidal Silica Polishing Suspension (CMP Slurry)

Colloidal silica suspension is able to produce the ultimate in high quality mirror polishes on polishing machine. One of the disadvantages of colloidal silica is that it can crystallise out of solution. The crystals have a corrosive action and can attack material.

Polishing Slurry for Silicon Nitride (Ceramic) - Col-K(R)

Col-K(R) has been designed for polishing silicon nitride, glass, sapphire, alumina, and metal/ceramic composites. It proves exceptionally effective during the final polishing steps for silicon nitride.

Polishing Slurry for Titanium - Col-K(X)

Col-K(X) has been specially developed to mirror polish Titanium without the need for any chemical additives.

Polishing Slurry for Stellite and Cobalt Chrome - Col-K

A part abrasive, part chemical polishing action makes COL-K well suited to polishing difficult materials such as Stellite and Cobalt Chrome. A Liquid polish used on Kemet CHEM Cloth to produce the ultimate in high quality mirror polishes on cmp polishing machines.

| Product | Size | ||

|---|---|---|---|

| 1 Litre | 5 litres | 20 Litres | |

| Col-K, 0.09 μm | 600262 | 600212 | 600204 |

| Col-K (R), 0.09 μm | 600269 | - | - |

| Col-K (X), 0.09 μm | - | 600267 | - |

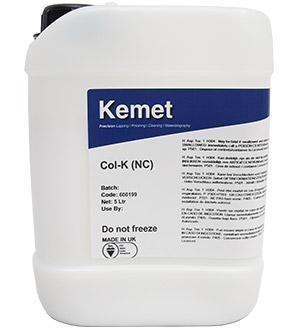

| Col-K (NC), 0.09 μm | 600261 | 600199 | 600202 |

Non-Crystallising Polishing Slurry

Kemet has developed the next generation of colloidal silica – a non crystallising version called Kemet Col-K (NC). This is available in 1, 5 and 20 litre containers.

Effect of using colloidal silica on a lapping machine. Notice the white residue (crystals) on the machine.

Effect of using Kemet Col-K (NC) on a Kemet 15 Lapping machine. Notice that there is no white residue on the machine.

FAQ of Colloidal Silica

What is Colloidal Silica

Colloidal silica refers to a suspension of very fine, solid, amorphous silica particles in a liquid. The term "colloidal" indicates that the particles are small enough to remain evenly dispersed in the liquid without settling to the bottom. Silica is a compound composed of silicon and oxygen, and in the colloidal form, it has unique properties that make it useful in various applications.

The particles in colloidal silica are typically in the nanometre range, which means they are extremely small. Colloidal silica particles have a high surface area and can remain suspended in a liquid for long periods due to electrostatic repulsion and steric hindrance, preventing them from agglomerating or settling. The properties of colloidal silica can be tailored by adjusting parameters such as particle size, concentration, and surface chemistry.

Colloidal silica is often used in the semiconductor industry and precision optics for achieving a flat and smooth surface on silicon wafers.

Is Colloidal Silica dangerous

Colloidal silica is generally considered safe for use in various industrial and commercial applications when handled properly and in accordance with recommended safety precautions. However, like many chemical substances. Col-K has the potential to cause skin sensitisation due to the presence of certain preservatives.

Colloidal Silica vs Fumed Silica

Colloidal silica and fumed silica each have distinct characteristics and are applied in different ways due to their physical forms, particle sizes, and surface chemistries. The choice between them is often dictated by the specific needs of the intended application, whether it involves liquid suspensions and customisation (colloidal silica) or finely dispersed powders with rheological modification capabilities (fumed silica).

Colloidal Silica vs Lithium Silicate

The primary differences between colloidal silica and lithium silicate lie in their chemical compositions, forms, and applications. Colloidal silica is characterised by silicon dioxide particles in a liquid suspension, offering versatility for polishing, coatings, and various industrial uses. In contrast, lithium silicate, with its lithium, silicon, and oxygen components, is applied in concrete treatments and coatings, showcasing alkaline properties and contributing to enhanced durability in specific settings. The choice between the two depends on the desired properties and intended applications within different industries.

Does Colloidal Silica expire?

While colloidal silica may not have a fixed expiration date, Kemet recommends that it is stored in cool, dark conditions and be used within 12 months. Periodic checks of the product's appearance and stability may also be useful, especially if it has been stored for an extended period. If you notice significant changes in the appearance, texture, or performance of colloidal silica, or if it has been stored under less-than-ideal conditions, it may be best to conduct Kemet on whether the product is still suitable for its intended use.