Sapphire Lapping and Polishing Process

Single Crystal Sapphire

The use of Single Crystal Sapphire, as a high quality original opto-mechatronic material in the information age, is growing rapidly because of its excellent mechanical features such as stability and optic permeability.

Problems on processing Sapphire

- Sapphire has the property of extremely high hardness but very low impact strength.

- LED chips have the above structure but because the sapphire substrate is susceptible to stress there is the fear that it can easily be damaged.

- Because of this inherent characteristic the wafer cannot be diced with a diamond wheel. Scribing is used for this purpose.

- In order to produce a wafer thickness suitable for scribing we must perform back-grinding, followed by lapping and polishing.

- Because the final thickness of the wafer is about 80um it is very weak and it is very important to keep it from breaking.

- As this back-grinding/lapping/polishing is the final manufacturing process it has a great effect on yield.

- These final operations demand machines and processes of high accuracy, high efficiency, and high stability in the manufacturing method.

Kemet has developed a series of metal-composite lapping plates to shorten the lapping and polishing process and reduce the number of reject parts.

Kemet Copper SP2 Composite Plate

This is the most popular plate for Sapphire lapping

The Kemet Copper SP2 Plate is a Metal/resin composite containing finely graded copper powders. It was developed for the sapphire lapping market to produce repeatable stock removal of up to 2μm per minute.

Other plates which are used for sapphire lapping are:

Kemet Copper SP3 Composite Plate

This is a harder version of Kemet Copper SP2 which gives a faster removal rate.

Kemet XJ2 Composite Plate

This gives the fastest removal rate.

Kemet XP Composite Plate

Slower removal rate than Kemet Copper SP3 but with better Ra. Polishing Plates are manufactured from a homogenous mix of synthetic resins, copper powder and other materials. The Kemet XP plate is used to polish a wide variety of materials

| Kemet Plate | Features | Relative Removal compared to Pure Copper | Typical Surface Finish (Ra) |

|---|---|---|---|

| Pure Copper | 1 | 5.6nm | |

| Kemet Copper SP2 | Good removal rate and Ra, easy to groove | 1.25 | 6.3nm |

| Kemet Copper SP3 | Better removal rate but worse Ra. More difficult to groove | 1.6 | 8.1nm |

| Kemet XP | Better removal rate and good Ra. More difficult to groove | 1.5 | 5.5nm |

| Kemet XJ2 | Best removal rate but worse Ra, easy to groove | 1.7 | 10.6 nm |

Kemet Iron SP2 Composite Plate

This plate is used as an alternative to Kemet Copper SP2 where copper must not come into contact with the sapphire wafer egg for the manufacture of blue/green LED’s

The Kemet Iron SP2 Plate is a Metal/resin composite containing finely graded iron powders. It was developed for the sapphire lapping market to produce repeatable stock removal.

Kemet XL Composite Plate

Polishing plate which gives an excellent surface finish e.g. when used with 3 micron diamond slurry Ra = 1.4nm

Kemet XL Composite Polishing Plate gives good stock removal, whilst producing high quality surface finish and flatness with Kemet Diamond Slurries.

Typical Sapphire Polishing Processes

Sapphire Substrates

- Double-sided lapping with Boron Carbide #240 abrasives on cast iron plates to achieve the required thickness and surface roughness.

- Single-sided lapping with Kemet SP2 plate with either 3 or a 6 micron diamond slurries.

- Single-sided CMP process with polyurethane or poromeric pads with colloidal silica slurries.

MOCVD

- Single-sided diamond wheel grinding (also known as back grinding).

- Single-sided lapping with Kemet SP2 plate with 3 or 6 micron diamond slurries, (for this application, most of the LED manufacturers stops at this process stage).

Phone cover glass, panels, watch faces and windows

- Double-sided lapping with either boron carbide #400 abrasives on cast iron plates or fine grinding wheels.

- Single or double-sided machines process with Kemet Copper SP2 plates with 3 or 6 micron diamond slurries.

- Single or Double-sided CMP process with polyurethane or poromeric pads with colloidal silica.

Polishing Sapphire - Case Study

Test Requirements: To achieve a surface finish better than 60/40 scratch dig on both sides of sapphire wafers.

Component/Material: Sapphire wafers

Machine Type: Kemet 15 Lapping Machine

| Process Breakdown | |||

|---|---|---|---|

| Stage | Plate/cloth type | Abrasive type/grade | Process time |

| 1 | Kemet XP | Kemet Diamond Slurries | 20 mins per side |

| 2 | Pure Tin | Kemet Diamond Slurries | 10 mins per side |

Sapphire wafers were treated for 20 mins per side on Kemet XP using Kemet Diamond Slurry. A further 3 samples were treated for 10 mins per side on a Pure Tin plate using Kemet Diamond Slurry.

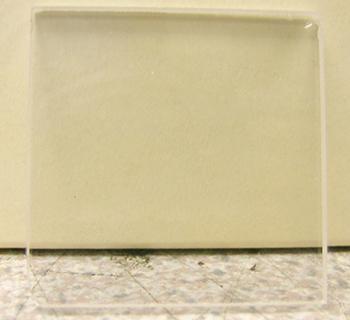

Pre-Processed Sapphire

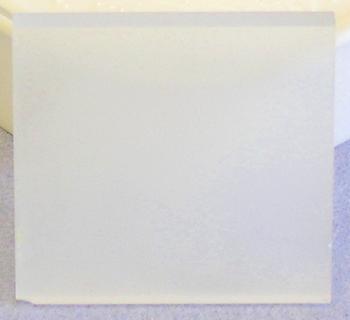

Sapphire after Stage 1

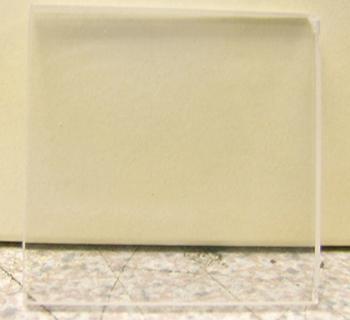

Sapphire Polished Final Stage