Ultrasonic Cleaning Watches

Ultrasonic cleaning is used by nearly all big watch manufactures as a key manufacturing & servicing tool. You should never clean a complete watch as the ultrasonic vibrations may undo mechanical mechanisms and damage the watch, also another point to consider is drying, ultrasonic cleaners are aqueous based cleaners and water may get trapped inside damaging the watch. The watch should be dismantled before cleaning. Generally, watch cleaning ultrasonic use 40Khz generators as this produces a finer implosion and cavitation, thus improving on precision cleaning and reducing the risk of cavitation erosion on non-ferrous metals. The right cleaning agent is a very important factor in the process as this could also damage parts. Ideally using a neutral agent such as ‘Galvex 18.01’ which has excellent watch cleaning properties and will not damage any components.

Stage 1 – Ultrasonic wash

The Kemet 6 benchtop cleaner was filled with tap water and allowed to heat up to the required temperature of 60°C. The unit was set to degas whilst heating, the degas function removes small suspended gas bubbles which in turn increases the cavitation effect. Once at the correct temperature a 3% concentration of Galvex 18.01 was added to the tank and allowed to degas for a further 10 minutes.

A number of watches were cleaned during the trials including a range of different materials. On average the watch straps had a 5 minute cleaning cycle in the Galvex 18.01, whilst the more heavily contaminated straps required a 20 minute cycle.

All watches were placed inside the basket and submerged in the tank. Note- the watch face on some samples were left on during cleaning, we do not recommend this. These items were scrap and were used for testing purposes only.

Stage 2 – Ultrasonic rinse

The watches then required rinsing after cleaning to remove any remaining debris and cleaning detergent residue. Rinsing is an important stage which can be over looked but to ensure optimal results Kemet recommend at least one high quality deionised water rinse with ultrasonic cavitation to ensure optimal results.

Stage 3 – Hot air dryer

Lastly the watches were then dried using a hot air drying unit at 70°C for 5 minutes.

Before and after results for Ultrasonic Cleaning Watches

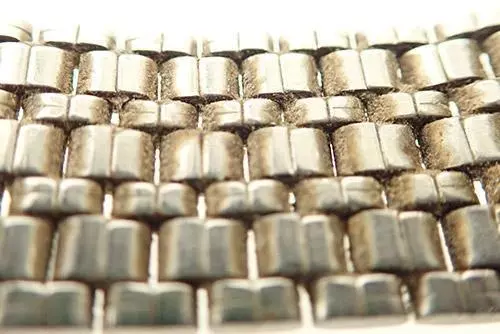

With the watch strap below, if the contamination is left on the surface for a long period of time this can attach and cause pitting on the plating. See how the contamination has been removed but the plating has been pitted. This would then need to be grinded/polished using Kemet DiaVers Diamond Paste for a perfect watch strap finish.

The watch face is left on in most of these examples and is not recommended. This will run the risk of water entering or condensation forming and in some cases the glass will also come off from the watch face.