Surface Finish Inspection Inside Slots

Manufacturing industries have been adopting more advanced techniques to produce precision components. One of the key features of these components is their surface finish, which is a critical aspect in determining the functional efficiency of the component. Surface finish is often defined as the texture left on a surface after it has been machined or treated. Surface finish is not only a cosmetic requirement but also a functional one. The surface finish of a component affects its tribological behaviour, which in turn affects its performance and lifespan. Moreover, the surface finish also affects the fluid flow and heat transfer characteristics of the component. Slots, especially narrow slots, pose a challenge for surface finish inspection. A smooth and uniform surface finish inside the slots is required for various applications, including bearing surfaces, fluid flow control surfaces, and electrical insulation surfaces. In these applications, the smoothness of the surface directly affects the efficiency and performance of the component.

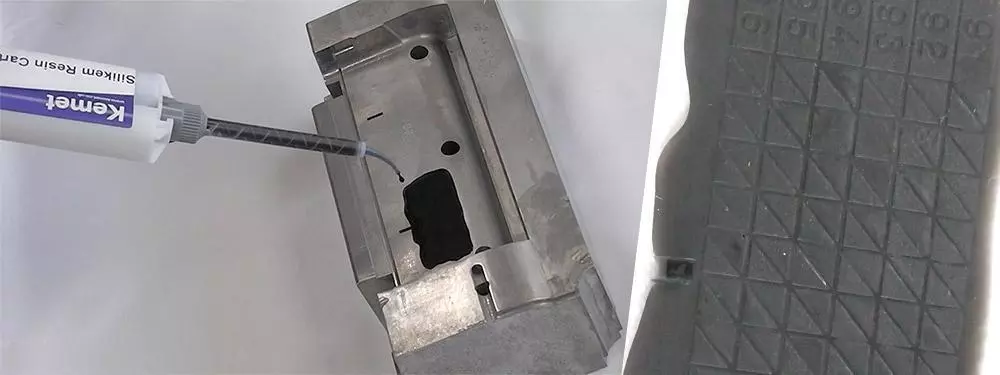

The SiliKem compound has established itself as an efficient tool for visual inspection of complex, hard-to-reach areas in mould tools. With the ability to deliver precise results in a matter of minutes, SiliKem provides a sense of assurance and confidence to its users. SiliKem's accuracy is unmatched, with a resolution of 0.1μm, making it possible to detect even the smallest of scratches on a surface. This level of precision is made possible due to the elastic nature of SiliKem, which allows for easy removal from the mould without any damage to the tool. Additionally, the versatility of SiliKem makes it a valuable tool for inspection of undercuts, a common challenge in mould tool design. The use of SiliKem is convenient, with a maximum cure time of only three minutes from mixing to the finished sample. Furthermore, SiliKem is a non-hazardous substance, eliminating any safety concerns during the inspection process. The absence of heat generation during the curing process is another benefit, allowing for a safe and efficient inspection process.

| Product | Code | |

|---|---|---|

| SiliKem Resin Cartridge (includes 6 nozzles) | 339805 | |

| Dispensing Gun | 339217 | |

| Mixing nozzles | 48 pack | 339801 |

| 12 pack | 339804 | |

| Nozzel Tips (For use in hard to reach areas) | 50 pack | 339806 |

Our team is available to provide a complimentary demonstration of this product at your facility anywhere within the United Kingdom. This opportunity will provide you with an in-depth understanding of the benefits this can bring. Please don't hesitate to reach out to us to schedule your demonstration.