Ultrasonic Cleaning Line Transport Systems

Kemet offer a range of transport systems to help assist the operator moving the baskets through different stages of the ultrasonic cleaning line. The' PTM30 Easy Lift' sytem helps the operator move the baskets manually to each stage.

The 'MBT' Multi basket transport systems can handle several baskets simultaneously and automatically based on inductive sensor. The basket is transferred through the wash process and finishes on the unloading station automatically when complete.

Both MBT units below have an HMI touch screen panel which includes the below features:

- Program menu

- 10 programs

- Ultrasonic, Jet, Air bubble, Dunking on/off

- Treatment time 0…59 min 59 sec

- Dripping time 0…59 min 59 sec

- Dunking after treatment time (max 10)

- Control menu

- Temperatures

- Tank heating mode: off, continuous, 7-day timer

- Dryer heating mode: off, continuous, runtime

- Filtration mode: off, continuous, no treatment, 7-day timer Autofill on/off

PTM30 Easy Lift - Ultrasonic Cleaning Transport System

- Movement is controlled with a handle attached to the sledge. Up/down pneumatic assist is controlled with thumb switches.

- Requires additionally loading/unloading tables

- Vertical movement is assisted by pneumatic cylinder

- Horizontal movement is by sliding the sledge on the rail

- Max load - 30 kg

- Compressed air inlet - R1/4

TD15 MBT - Ultrasonic Cleaning Transport System

- Transporter is mounted on the tank unit Loading/ unloading tables at both ends of the line

- Standard process direction from left to right

- Maximum load 15 kg including basket

- Up to 4 stages as standard, further stages as separate option

- Horizontal and vertical movement with DC motors

- Horizontal speed max. mm/s, vertical speed max. mm/s

- Separate electric cabinet

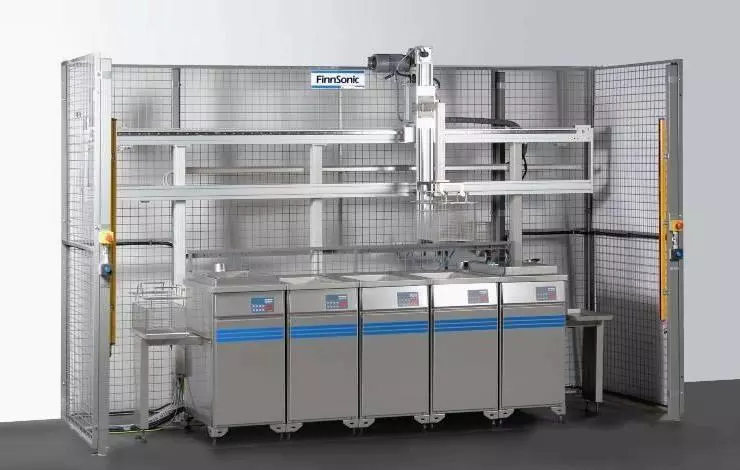

TD35 MBT - Ultrasonic Cleaning Transport System

- Transporter is mounted on the tank unit Loading/ unloading tables at both ends of the line

- Safety fence surrounding the line from behind (tank valves are accessible) and at both ends, light curtain on the front side with reset buttons

- Optional fluid handling modules behind tank line are accessible and outside of fenced area

- Standard process direction from left to right

- Maximum load 35 kg including basket

- Up to 4 stages as standard, further stages as separate option

- Horizontal and vertical movement with inverter controlled motors

- Horizontal speed max. 435 mm/s, vertical speed max. 100 mm/s, slow lifting (option) speed 5,7 mm/s

- Separate electric cabinet