Handheld machine for Valve Grinding Gate Valves and Wedges with Flat Seats

Model SH - Suitable for valves with flat seats ø 10 - 50mm (0.4” - 2”)

The SH model is designed for valves with flat seats ranging in size from ø 10 - 50mm (0.4” - 2”). It comes equipped with an air drive unit that operates at a standard pressure of 6 - 7 bar, allowing for various grinding speeds that enable close control of the finished surface. The machine requires only three sizes of abrasive discs to cover the full seat size range, and self-adhesive grinding discs make for quick and easy attachment to the grinding heads. The SH model is supplied with rough, medium and fine grinding discs, and additional self-adhesive grinding discs ranging from 40 to 1000 grit are also available. The complete machine and all necessary accessories are housed in a heavy-duty carrying and storage case for added convenience. For enhanced performance, diamond grinding discs are also available.

Maintaining gate valves and their wedges with flat seats is crucial for ensuring their proper functioning and preventing costly and dangerous failures. Valve grinding is a key process in this maintenance as it helps to restore the flatness and smoothness of the valve seats and wedges, thereby promoting a tight seal between the valve body and the gate. Proper maintenance through valve grinding can also extend the lifespan of gate valves, improve their performance, and reduce the likelihood of unplanned downtime, which can have significant financial and safety implications. Regular valve grinding can help to identify issues early, preventing further damage and potential failures.

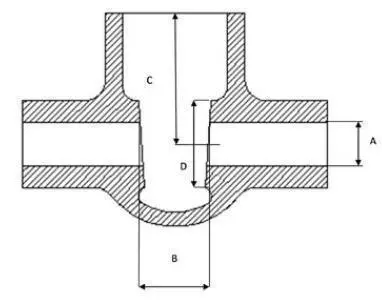

Possible range for Model SH:

A: 10 - 50 mm (0.4” - 2”)

D: 20 - 65 mm (0.8” - 2.5”)

B: 15 mm (0.5”)

C: 120 mm (4.7”)

Carrying case: 570 x 390 x 170mm (22.4” x 15.3” x 6.7”)

Total weight: 9 kg (19.8 lb)