Helilap Bore Finishing Tools

For extreme accuracy in production bore finishing, there is only one way to guarantee precision. This involves a Helilaps and an abrasive lapping and polishing medium or Kemet Diamond Compound.

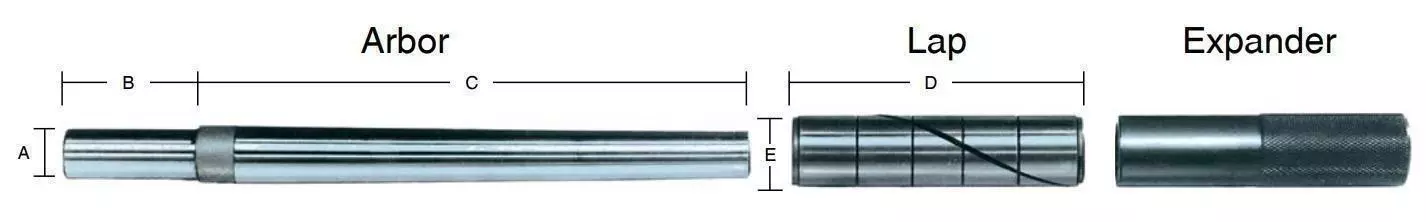

Manufactured from a uniform grade of annealed, close grained, grey cast iron, the lap incorporates a unique helical slot and external circumferential grooves. When the lap is slipped over the arbor and tapped gently with the lap expander, the internal taper in the lap and the taper on the arbor make contact, therefore allowing a precise degree of diametrical expansion to be achieved uniformly over the entire lap. This means that a Helilap gives a fast lapping action, perfect for bore roundness, exceptional straightness and superb surface finish. They are produced in a large range of sizes from 3/64" dia. to 3" dia as well as metric sizes.

Helilap Design

The Helilap, made of a good quality, close-grained, lapping iron has a tapered bore to enable it to slide on a high-tensile, hardened and ground steel Arbor. When the lap is driven up the Arbor, expansion occurs, and by utilisation of uniform points of contact around the circle, the roundness of bores and diameters can be held to extremely fine limits. Also, because the points of contact extend on the circle through the length of the lap, parallelism can be guaranteed. The lap will contract on being pulled down the slope of the Arbor but this contraction is limited and care should be taken in selecting the correct lap size. After use the lap should be removed from the Arbor so that it "relaxes" back to its original state.

Helilap Use

- If a bore in steel has a finished size of 0.252" (6.4mm) for example, consult the range chart (Appendix A). From this, choose the Ø 1/4" Helilap with No.3 Arbor and No.3 Expander. It can be seen that this lap covers a range of Ø 0.249" to Ø 0.264".

- If the component can be held by hand, rotate the lap in a lathe chuck at approx 500-600 rpm for Ø 1/4"

- Put some Kemet O.S Lubricating Fluid onto the Lap. Slide the component over the Lap. Keep on gently expanding the lap until slight resistance against the component can be felt

- At this point, stop the lap and apply some Kemet KD Diamond Compound. Restart and resistance should be felt.

- Transverse the component backwards and forwards along the rotating lap until resistance fades

- Re-expand the lap and continue.

- Regularly check the size and finish of the bore.

- During use reapply Kemet Diamond Compound. If the lap dries out, apply small quantities of Kemet OS lubricating fluid.

Kemet Diamond Compound

Kemet 14 Micron Diamond Compound used on steel will give a visual silky matt finish with Ra = 0.08 μm. This grade will also remove stock.

Kemet 3 Micron Diamond Compound used on a clean lap after Kemet 14 Micron Diamond Compound will give a polished finish with Ra = 0.03 μm.

Blind bores

When lapping blind bores, it is necessary to machine the lap so that only 50% of the lap contacts the bore. The arbor must also be reduced in length so that it does not foul the end of the blind bore. It is recognised that as the lap is expanded by driving the arbor into the lap, the end of the arbor could contact the end of the bore, so it is necessary to have different lengths of arbor for one lap. The accuracies achieved rely entirely on the supreme accuracy of that portion of the lap which is working within the bore.

Expanding Internal Helical Slot Laps

| Laps | Corresponding Arbors | Expanders | Pullers | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Lap dia ‘E’ | Length ‘D’ | Code | Arbor No. | Shank Dia ‘A’ | Shank Length ‘B’ | Taper Length ‘C’ | Code | Expander No. | Code | Size | Code |

| 3/64in | 1/2in | 303101 | 4/0 | 1/8in | 3/4in | 1 1/2in | 303401 | 4/0 | 303201 | Extra Small | 303301 |

| 1/16in | 5/8in | 303102 | 3/0 | 1/8in | 3/4in | 1 1/2in | 303402 | 3/0 | 303216 | ||

| 5/64in | 303103 | ||||||||||

| 3/32in | 3/4in | 303104 | 2/0 | 1/8in | 3/4in | 1 5/8in | 303403 | 2/0 | 303202 | ||

| 7/64in | 303105 | ||||||||||

| 1/8in | 7/8in | 303106 | 0 | 1/8in | 3/4in | 1 3/4in | 303404 | 0 | 303203 | ||

| 9/64in | 303107 | ||||||||||

| 5/32in | 303108 | ||||||||||

| 11/64in | 303109 | ||||||||||

| 3/16in | 1 3/8in | 303110 | 1 | 3/16in | 1in | 2 3/4in | 303405 | 1 | 303204 | Small | 303302 |

| 13/64in | 303111 | ||||||||||

| 7/32in | 1 3/4in | 303112 | 2 | 3/16in | 1in | 3in | 303406 | 2 | 303205 | ||

| 15/64in | 303113 | ||||||||||

| 1/4in | 2in | 303114 | 3 | 3/16in | 1in | 4in | 303407 | 3 | 303206 | ||

| 17/64in | 303115 | ||||||||||

| 9/32in | 303116 | ||||||||||

| 19/64in | 303152 | ||||||||||

| 5/16in | 2in | 303117 | 4 | 7/32in | 1in | 4in | 303408 | 4 | 303207 | ||

| 21/64in | 303153 | ||||||||||

| 11/32in | 303154 | ||||||||||

| 23/64in | 303118 | ||||||||||

| 3/8in | 2 1/2in | 303119 | 5 | 9/32in | 1 1/2in | 5in | 303409 | 5 | 303208 | ||

| 25/64in | 303120 | ||||||||||

| 13/32in | 303121 | ||||||||||

| 27/64in | 303122 | ||||||||||

| 7/16in | 2 1/2in | 303123 | 6 | 5/16in | 1 1/2in | 5in | 303410 | 6 | 303209 | ||

| 29/64in | 303124 | ||||||||||

| 15/32in | 303125 | ||||||||||

| 31/64in | 303166 | ||||||||||

| 1/2in | 3 1/4in | 303126 | 7 | 3/8in | 1 1/2in | 6in | 303411 | 7 | 303210 | ||

| 33/64in | 303127 | ||||||||||

| 17/32in | 303155 | ||||||||||

| 35/64in | 303156 | ||||||||||

| 9/16in | 303157 | ||||||||||

| 37/64in | 303174 | ||||||||||

| 19/32in | 303128 | ||||||||||

| 39/64in | 303168 | ||||||||||

| 5/8in | 3 1/4in | 303129 | 8 | 13/32in | 1 1/2in | 6in | 303412 | 8 | 303211 | large | 303303 |

| 41/64in | 303170 | ||||||||||

| 21/32in | 303130 | ||||||||||

| 43/64in | 303175 | ||||||||||

| 11/16in | 303131 | ||||||||||

| 45/64in | 303132 | ||||||||||

| 23/32in | 303133 | ||||||||||

| 47/64in | 303171 | ||||||||||

| 3/4in | 3 1/2in | 303134 | 9 | 1/2in | 2in | 7in | 303413 | 9 | 303212 | ||

| 49/64in | 303158 | ||||||||||

| 25/32in | 303135 | ||||||||||

| 51/64in | 303167 | ||||||||||

| 13/16in | 303136 | ||||||||||

| 53/64in | 303159 | ||||||||||

| 27/32in | 303160 | ||||||||||

| 55/64in | 303161 | ||||||||||

| 7/8in | 3 1/2in | 303172 | 10 | 9/16in | 2in | 7in | 303414 | 10 | 303213 | ||

| 57/64in | 303176 | ||||||||||

| 29/32in | 303144 | ||||||||||

| 59/64in | 303162 | ||||||||||

| 15/16in | 303137 | ||||||||||

| 61/64in | 303177 | ||||||||||

| 31/32in | 303138 | ||||||||||

| 63/64in | 303165 | ||||||||||