Emax Evolution Grinder and Polisher

A precision power hand tool system with a wide range of attachments suitable for grinding, smoothing, polishing and deburring. FiXpeed® system allows everyone to easily fix the speed of motor A and B independently prior to operation. For example motor A can be set to maintain the speed set by the FiXpeed® system while motor B has variable control using a foot controller. This function brings for unprecedented workability. 2 Types of Motors - Provides choice of various applications.

Emax Evolution Standard Set ((ENK-410S)

Capable for wide range of applications. An excellent total balance in motor performance and dimension against required rotational speed. 1,000~40,000 min-1

Emax Evolution Torque Set (ENK-250T)

For heavy duty and larger tools, Torque type promises to extend operation ranges. 1,000~25,000 min-1

Nakanishi (NSK) Smart Switch - The switch provides a click sensation and a confirmation tone is produced by the control unit when the switch is operated. The motor type is distinguishable by the switch colour.

One Touch Tool Changing - Ring Type (IR-310 Code: 339937) Easy twist open/close chuck.

Excellent Durability

High performance brushless motor eliminates the need of changing carbon brushes. RPM variation is minimal even when load changes. Allowing difficult and stable cutting in stress free motion. Suitable performance for finish grinding.

17 Type of Attachments for All Type of Applications

Capable of infinite applications with 14 different handpieces and 3 types of intermediate attachments.

| Model | Set | Standard Accessories | Code |

|---|---|---|---|

| EV410-120 (120V) | Standard | Micro Grinder (IR-310+ENK-410S) : 1 pc. Collet Chuck ø3.0 mm (CHH-3.0), ø2.35 mm (CHH-2.35) : 1 pc. each Control Unit (NE249) : 1 pc. Handpiece Holder : 1 pc. Handpiece Stand : 1 pc. Power Supply Cord : 1 pc. Spanner (7 x 5.1) : 1 pc. Pin Spanner (K-233) : 2 pc. L Shaped Spanner : 1 pc. | 340436 |

| EV410-230 (230V) | 339920 | ||

| EV250-120 (120V) | Torque | Micro Grinder (IR-310+ENK-250T) : 1 pc. Collet Chuck ø3.0 mm (CHH-3.0), ø2.35 mm (CHH-2.35) : 1 pc. each Control Unit (NE249) : 1 pc. Handpiece Holder : 1 pc. Handpiece Stand : 1 pc. Power Supply Cord : 1 pc. Spanner (7 x 5.1) : 1 pc. Pin Spanner (K-233) : 1 pc. L Shaped Spanner : 1 pc | 340437 |

| EV250-230 (230V) | 339921 |

| Product | Description / Standard Accessories | Model | Code | |

|---|---|---|---|---|

| Emax EVOlution Control Unit | Weight : 2.3 kg Power Source : AC 120/230V, 50-60Hz Dimensions : W130 x D254 x H97 mm | NE249 120 | 340438 |

| NE249 230 | 339922 | |||

| Standard Type Motor with Cord | Weight : 90 g (w/o Cord) with Straight Cord 1.5m Max. Torque 4.3 cN·m Max. Power : 73W Speed : 1,000~40,000 min-1 Accessory : Pin Spanner (K-233) 1 pc. | ENK-410S | 339923 |

| Torque Type Motor with Cord | Weight : 147 g (w/o Cord) with Straight Cord 1.5m Max. Torque 4.8 cN·m Max. Power : 76W Speed : 1,000~25,000 min-1 | ENK-250T | 339924 |

| Ring Type Attachment | Weight : 92 g Collet Chuck : ø3.0mm (CHH-3.0), ø2.35mm (CHH-2.35) Accessory : Spanner (7 x 5.1) 1 pc. Pin Spanner (K-233) 1 pc. L Shaped Spanner 1 pc. 40,000 min-1 Max. (*) 40,000 min-1 Max. (*2) | IR-310 | 339937 |

| Lever Type Attachment | Weight : 62 g Collet Chuck : ø3.0mm (CHH-3.0), ø2.35mm (CHH-2.35) Accessory : Spanner (7 x 5.1) 1 pc. Pin Spanner (K-233) 1 pc. 40,000 min-1 Max. (*) 40,000 min-1 Max. (*2) | IH-300 | 340271 |

| Straight Type Attachment | Weight : 55 g Collet Chuck : ø3.0mm (CHH-3.0), ø2.35mm (CHH-2.35) Accessory : Spanner (7 x 5.1) 1 pc. Bar Wrench (PCR-30) 1pc. 40,000 min-1 Max. (*) 40,000 min-1 Max. (*2) | IG-400 | 340410 |

| 6 mm Torque Type Attachment | Weight : 210 g Collet Chuck : ø6.0mm (CHG-6.0) Accessory : Spanner (10 x 10) 1 pc. Bar Wrench (K-212) 1 pc. Pin Spanner (K-233) 1 pc. * Use 6mm torque Type HG-200 to connect ENK-250T 30,000 min -1 Max. (*) 27,000 min-1 Max. (*2) | HG-200 | 340242 |

| Long Type Attachment for Deep Hole Grinding ø13 mm | Weight : 156 g Collet Chuck : ø3.0mm (CHM-3.0) Accessory : Spanner (7 x 5.1), (6 x 4.5) 1 pc. each Pin Spanner (K-233) 1 pc. 35,000 min-1 Max. (*) 35,000 min-1 Max. (*2) | BMH-300 | 340245 |

| 90º Mini Angle Type Attachment for Chamfering Deep Hole (Very Small Head) | Weight : 47 g Speed Reduction Ratio : 10/11 Collet Chuck : ø1.6mm (K-253) Accessory : Chuck Wrench (K-232) 1 pc. Pin Spanner (K-233) 1 pc. 15,000 min-1 Max. (*1) 15,000 min-1 Max. (*2) | MFC-300M | 340248 |

| 90º Mini Angle Type Attachment for Chamfering Deep Hole | Weight : 50 g Speed Reduction Ratio : 10/11 Collet Chuck : ø1.6mm (K-252) Accessory : Chuck Wrench (K-232) 1 pc. Pin Spanner (K-233) 1 pc. 15,000 min-1 Max. (*1) 15,000 min-1 Max. (*2) | MFC-300S | 340247 |

| 90° Angle Attachment | Weight : 45 g Collet Chuck : ø3.0mm (CHC-3.0) Standard Accessories (Rubber Pad, Paper Disk) Accessory : Standard Accessories 1 set. Chuck Wrench (K-231) 1 pc. Pin Spanner (K-233) 1 pc. 35,000 min-1 Max. (*1) 20,000 min-1 Max. (*2) | IC-300 | 340272 |

| 50° Angle Attachment | Weight : 45 g Collet Chuck : ø3.0mm (CHC-3.0) Standard Accessories (Rubber Pad, Paper Disk) Accessory : Standard Accessories 1 set. Chuck Wrench (K-231) 1 pc. Pin Spanner (K-233) 1 pc. 35,000 min-1 Max. (*1) 20,000 min-1 Max. (*2) | KC-300 | 340273 |

| Mini-luster Attachment (Pencil-Type Polisher) (Reciprocating motion) | Weight : 130 g Max. tool shank diameter ø3.2mm, Screw clamp type. Stroke range (fixed) : 0.8mm Accessory : Standard Accessories 1 set 35,000 min-1 Max. (*1) 30,000 min-1 Max. (*2) | ML-8 | 340252 |

| Swing-luster Attachment (Pencil-Type Polisher) (Right to Left motion) | Weight : 127 g Reciprocating Stroke (Variable) : 0~9,000 times/min. Stroke range (Variable) : 0~1.6mm Max. tool shank diameter ø5.0mm, Screw clamp type. Accessory : Standard Accessories 1 set 35,000 min-1 Max. (*1) 24,000 min-1 Max. (*2) | SLS-16 | 339878 |

| Fine Belt Sander Attachment | Weight : 350 g Belt Speed : 0~825 m/min. Belt Width : 4, 6, 8mm Accessory : 8, 6, 4mm Belts. Allen Wrench (3mm ) : 1 pc. 35,000 min-1 Max. (*1) 35,000 min-1 Max. (*2) | KBS-101 | 340256 |

| Hammer Attachment for Engraving and Ornament Processing Work | Weight : 95 g Stroke Times : 25~5,000 times/min. Stroke Spring Pressure : 4.4~7.1N (Ring Adjustment Type) Accessory : Spanner (7 x 5.1) 1 pc. Bar Wrench (K-212) 1 pc. Oil and nozzle, Hammer Bit (For replacement) 2 pcs. 20,000 min-1 Max. (*1) 16,000 min-1 Max. (*2) | HA-500 | 340750 |

| Luster Attachment (Pistol-Type Polisher) (Reciprocating motion) Built-in Motor | Weight : 800 g Max. Torque 17.2 cN·m with Straight Cord 1.5m Stroke Range : 0~6mm (variable) Max. tool shank diameter ø6.4mm, Screw clamp type. Reciprocating Stroke (variable) : 0~7,600 times/min Accessory : Standard Accessories 1 set Lubrication Oil, Lubrication Nozzle for LUSTER 30,000 min-1 Max. (*1) 30,000 min-1 Max. (*2) | NLS-110 | 340283 |

| Luster Attachment (Pistol-Type Polisher) (Reciprocating motion) | Weight : 680 g Stroke Range : 0~6mm (variable) Max. tool shank diameter ø6.4mm, Screw clamp type. Reciprocating Stroke (variable) : 0~7,600 times/min Accessory : Standard Accessories 1 set. Lubrication Oil, Lubrication Nozzle for LUSTER 30,000 min-1 Max. (*1) 30,000 min-1 Max. (*2) | LS-100 | 340251 |

| EXTENSION JOINT | Weight : 83 g Pin Spanner (K-233) : 1 pc. 35,000 min-1 Max. (*1) 35,000 min-1 Max. (*2) | CN-01 | 340260 |

| (1/4) Speed Reducer | Weight : 68 g Pin Spanner (K-233) : 1 pc. 30,000 min-1 Max. (*1) 30,000 min-1 Max. (*2) | RG-01 | 340258 |

| (1/15) Speed Reducer | Weight : 93 g Pin Spanner (K-233) : 1 pc. 30,000 min -1 Max. (*1) 30,000 min -1 Max. (*2) | RG-02 | 340259 |

| Product | Fit to (Model) | Inside Diameter : ød mm | Model | Code |

|---|---|---|---|---|

| IC-300, KC-300 | ø1.6 | CHC-1.6 | 340624 |

| ø2.35 | CHC-2.35 | 340604 | ||

| ø3.0 | CHC-3.0 | 340608 | ||

| ø3.175 | CHC-3.175 | 340603 | ||

| HG-200 | ø2.35 | CHG-2.35 | 340611 |

| ø3.0 | CHG-3.0 | 340620 | ||

| ø3.175 | CHG-3.175 | 340610 | ||

| ø5.0 | CHG-5.0 | 340634 | ||

| ø6.0 | CHG-6.0 | 340612 | ||

| ø6.35 | CHG-6.35 | 340617 | ||

| ø1.0 - ø6.35 available on request | ||||

| IH-300, IR-310 | ø1.5 | CHH-1.5 | 340635 |

| ø2.35 | CHH-2.35 | 340607 | ||

| ø3.0 | CHH-3.0 | 340613 | ||

| ø3.175 | CHH-3.175 | 340602 | ||

| ø1.0 - ø3.175 available on request | ||||

| BMH-300 | ø1.0 | CHM-1.0 | 340636 |

| ø1.6 | CHM-1.6 | 340637 | ||

| ø2.0 | CHM-2.0 | 340638 | ||

| ø2.35 | CHM-2.35 | 340609 | ||

| ø3.0 | CHM-3.0 | 340615 | ||

| ø3.175 | CHM-3.175 | 340630 | ||

| MFC-300S | ø1.6 | K-252 | 340626 | |

| MFC-300M | ø1.6 | K-253 | 340924 | |

| IG-400 | ø2.35 | NKM6-2.35 | 340632 |

| ø3.0 | NKM6-3.0 | 340631 | ||

| ø3.175 | NKM6-3.175 | 340633 | ||

Chuck Nut

IG-400 (for NKM6 Group)

Model: CHN-6

Code: 340639

| Product | Description | Model | Code |

|---|---|---|---|

| Straight Cord : 1.5 m (with Switch) | ENKCD-250T (Torque Type Motor) | 340044 |

| ENKCD-410S (Standard Type Motor) | Available on request | ||

| Power Supply Cord | K-269 | 340762 |

| Foot Control (ON-OFF and speed change can be accomplished.) | FC-64 | 340749 |

| Handpiece Holder | K-273 | 340726 | |

| Handpiece Stand | K-274 | 340434 |

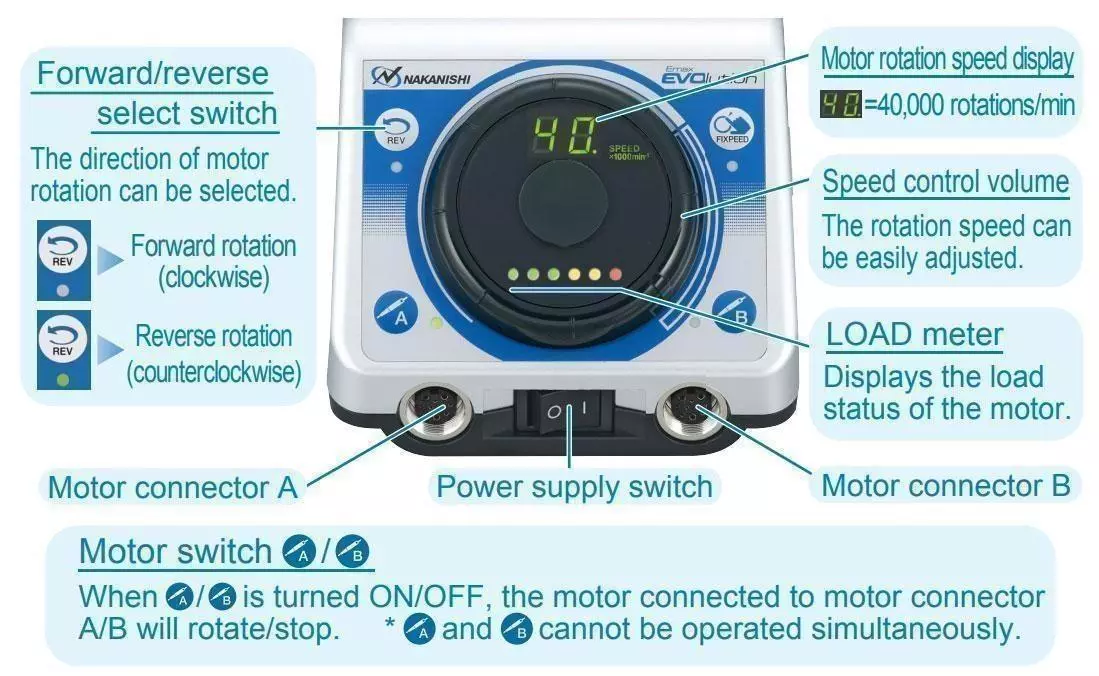

How to operate the Emax EVOlution

How to change tools on the NSK emax evo

- Loosen the ring and remove the tool

- Replace the tool and tighten the ring until a click sound is produced

How to start the NSK emax evo control unit

- Turn speed control volume completely to the left.

- Switch ON the power supply

* Please make sure that the speed control display is set to 1.

How to start/stop the motor and adjust the rotation speed

- To start - Press

or the motor smart switch. The motor starts to rotate

or the motor smart switch. The motor starts to rotate - To stop - When the motor is rotating, press

or the motor smart switch. The motor stops rotating.

or the motor smart switch. The motor stops rotating.

To adjust the rotation speed

- Turn the speed control volume to adjust the rotation speed

FIXPEED function

FIXPEED allows everyone to set the speed of the motor in advance. The speed that is frequently used can be easily set at the touch of a button

Daily maintenance for NSK Emax attachments

Common procedures

Clean the collet with a cloth or cotton swab moistened with alcohol. This maintains run-out accuracy and prevent the collet from sticking.

Clean the tapered part (the hole where the collet is inserted) with a cloth or cotton swab moistened with alcohol. However, do not blow air as dust may enter the inside of the attachment. This maintains run-out accuracy and to prevent collets from sticking.

Remove the attachment from the motor periodically as it gets tightened hard while in use. This is required to prevent the attachment from sticking to the motor.

If the attachment cannot be removed from the motor, remove using tools for motor connection, such as the pin spanner or bar wrench supplied with the attachment. Wear a non-slip work glove on the hand that holds the motor. If the motor still cannot be removed, have it sent for repair.

e.g. IR-310 + ENK-410S

- Prepare the pin spanner supplied with the attachment.

- Prepare a non-slip work glove. If not available, wrap the motor with something that will prevent slipping.

- Fit the pin spanner on the attachment and turn it counterclockwise to loosen it.

Since bearings are consumables, motor spindles should be sent periodically to Nakanishi for overhaul. If you hear abnormal noise or feel a decline in run-out accuracy, have it overhauled.

Maintenance procedures for IR-310, IH-300, EHR-500, and EHL-401

Adjust the collet periodically, this prevent the collet from sticking.

How to adjust the collet (If the tip tool does not come off or does not fit in, loosen the collet by referring to the following.)

- Set the ring (or lever) to OPEN.

- Insert the test bur or the tip tool in the collet, turn the collet clockwise with fingers until it stops and install it.

- From that state, turn the collet approx. 1/5 to 1/4 counterclockwise and adjust the collet so that the tip tool can be loosely pulled out.

- Set the ring (or lever) to LOCK, and if the tip tool cannot be pulled out, the adjustment is completed.

If the collet cannot be turned with fingers, follow the below instructions.

- Prepare 2 types of wrenches (7 x 5.1 and L-shaped wrench) supplied with the attachment.

- Set the ring to LOCK.

- Align the flat part of the spindle shaft (the part that rotates) with the slit at the tip of the attachment.

- Fit the L-shaped wrench on the slit to secure the spindle shaft. If step3 is not done properly, the L-shaped wrench will not properly fit.

- Set the ring to OPEN.

- Fit the 5.1 side of the 7 x 5.1 wrench on the collet and turn it counterclockwise.

- As the collet loosens, it pops up as shown in the photo.

- After loosening the collet to the maximum extent, pull the collet to remove it. If the collet still cannot be pulled out, or if the collet cannot be loosened even by using a wrench, have it sent for repair.