Vickers & Knoop Fully Automatic Hardness Testing

Smart hardness testing with great performance

The DUROLINE LV Series is a highly versatile and sophisticated hardness tester system designed for various applications in the fields of quality assurance, quality control, research, and metallurgical departments. This system is perfect for monitoring the hardness of metal parts and alloys during fabrication, post heat treatment or welding, and for performing performance analysis on new alloys.

The system is capable of determining the Vickers micro and macro-hardness of a wide range of materials, including steel alloys and metal components, small precision parts, thin material or wire, and coatings. It is also capable of performing case depth determinations (CHD, EHT, NHT) on cross sections, both manually and automatically, making it ideal for a wide range of applications.

Whether you're working in a research laboratory, metallurgical department, or manufacturing facility, the DUROLINE LV Series offers advanced features, including a highly accurate measurement system and robust opto-mechanical design, to ensure reliable results every time. This system meets the latest ISO, ASTM, and JIS standards and is an essential tool for those looking to achieve high levels of quality control in their work.

- Load range that is both micro and macro for HV/HK scales, with a capacity of 100gf to 10kgf.

- Load application that is controlled through a closed-loop system utilising load cell technology.

- Auto-measurement feature with a zoom window for increased accuracy.

- N-Sure, a flexible hardness test and measurement programme based on Windows 10.

- Test result and report database generation.

- A 22" full HD capacitive 10-point multi-touch desktop monitor.

- An integrated high-resolution 5.0 MP camera with zoom capability and a USB3.0 interface.

- LED light source with a built-in controller.

- An integrated Windows-operated mini-PC with Intel and SSD specifications.

- Network interface options including USB (x4), Displayport (x2), LAN (x1), and Wireless LAN.

- An extremely robust opto-mechanical system.

- The latest generation of electronics and motors integrated into the system for reliable performance.

- User-friendly with remote accessibility for service purposes.

- Meets the latest ISO, ASTM, and JIS standards.

The DUROLINE LV-Series Hardness Tester is the result of a collaborative effort between an international, multi-disciplinary team with extensive experience in hardness testing. Utilizing the most advanced technology available, this system is designed to deliver fast cycle times with exceptional accuracy that conforms to international standards. The combination of a robust mechanical construction and integrated electronics system control, facilitated by fast CANBUS technology and a high-quality Windows-based mini-pc, results in a highly serviceable solution. The 10-point multi-touch screen interface, supported by a fast and secure display connection, greatly improves the monitoring of the hardness testing process. With its top-quality components and high-performance mini-pc, the DUROLINE LV Micro/Macro-Vickers Hardness Tester offers reliable and accurate automated indentation test and measurement capabilities that are guaranteed to provide consistent performance over many years.

Versatile micro+macro load range for HV/HK scales from 100gf to 10kgf

The DUROLINE LV Micro/Macro-Vickers Hardness Tester offers versatility and flexibility for micro and macro hardness testing across a wide range of loads, from 100gf to 10kgf. With the ability to select from nine different load steps for Vickers or Knoop testing, this system can accommodate any specimen within applicable standards. Loads can be quickly and easily set using the touch screen monitor menu icon, making the process user-friendly and efficient.

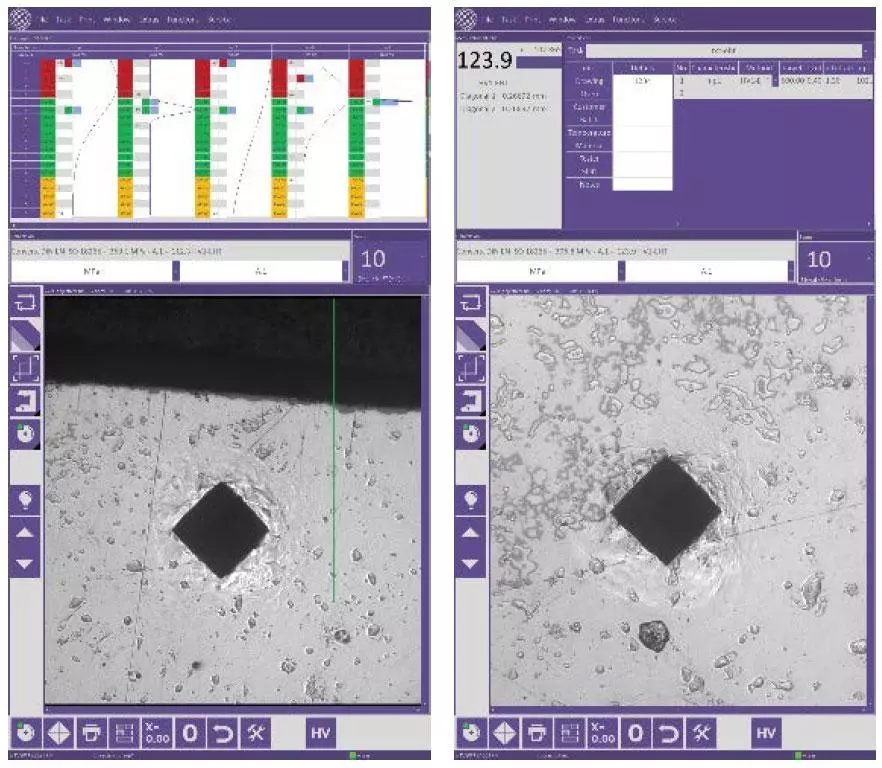

'N-Sure' Test and Measurement Software

The N-Sure Test and Measurement Software is an integral part of the DUROLINE LV Hardness Tester, providing a flexible Windows-based user interface that automates the test and measurement process. This results in improved productivity, increased operator efficiency, and reduced testing time, while also eliminating the need for costly and time-consuming rework. The N-Sure software also features multi-sample mount holders for automated testing of high-volume mounted samples.

The touch screen monitor provides clear images captured by the integrated camera, and the high-resolution display makes it easy for lab staff to analyze and discuss test results. The user-friendly program logic, combined with quick system settings, guides operators through the testing process, with Vickers or Knoop hardness values generated automatically on screen.

The DUROLINE LV Hardness Tester also features automatic light brightness adjustment for optimal image quality and accurate measurements. The LV2 and LV4 models are equipped with a motorized spindle and autofocus software module, ensuring sharp and accurate images in seconds.

- Automatic Light Brightness

- Automatic Focus (Available on LV2/LV4 models)

- Automatic Evaluation

- Database generating test results and reports

The system automatically evaluates the diagonals of indentation, providing immediate hardness values on screen. The N-Sure software program also provides advanced database management for test results and report generation, with the ability to save and retrieve measurement data for critical components in various industrial segments. Data can be stored and presented in standard or customized reporting forms, ensuring safe and organized management of test results.

Magnification range

The DUROLINE LV Series is a cutting-edge solution for micro/macro-hardness testing, offering a unique combination of high-performance digital cameras, LED illumination, and software with a range of available objectives. These tools are designed to deliver precise and accurate measurements in compliance with international standards, regardless of the test load.

High precision spindle with motorized option

One of the critical factors that determine the accuracy of hardness testing is the elevating speed and backlash of the spindle. The DUROLINE LV Series spindles are equipped with quality components and boast a robust design that ensures long-lasting performance and reliability. This also guarantees zero loss of accuracy over time due to wear and friction, even in automated Z-axis systems.

High precision spindle

The DUROLINE R-Series spindles are specifically designed for accurate Rockwell hardness testing. These spindles are engineered to withstand the Rockwell test force and maintain zero displacement during force application, ensuring the most accurate results. Like the LV Series, the R-Series spindles are built with quality components and designed for longevity, ensuring that the accuracy of the measurements will not degrade over time, even when testing large and heavy specimens.

Automatic Test Cycle

The Rockwell hardness testing process is fully automated, including preload application, main load application, and depth measurement, providing fast and convenient testing with maximum repeatability. With the DUROLINE LV and R-Series, manufacturers and quality control professionals can be assured that they are getting the most accurate and reliable results every time.

Fully Automatic Hardness Test & Measurement

The DUROLINE LV4 is a fully automatic test and measurement system that provides unparalleled precision and efficiency. Equipped with a high-precision motorized XY-stage with a 100x150 mm travel range and Autostage software module, this system offers a wide range of tests and measurements without the need for operator intervention.

The Autostage software module allows for easy customization of measurement parameters, including distance between measurements, distance from the edge, and the number of measurements. The measurement pattern can also be defined in a zigzag pattern and aligned with the edge angle of the sample with ease. Once the testing parameters have been set, the DUROLINE LV4 will automatically make indents at all testing points and measure the hardness, eliminating the need for manual intervention. In cases where manual measurement is necessary, it is simple to access any individual measurement point. Once all measurements are complete, test results can be generated in a comprehensive report format.

Scanning Overview Image Feature: The mapping function of the DUROLINE LV4 provides an overview image of the entire sample surface, allowing for the easy determination of test points based on pre-defined or user-defined patterns.

Case Hardening Depth (CHD) Testing: For case hardening depth (CHD) testing, a case hardening depth module is available for all DUROLINE M models. For the DUROLINE LV1 and LV2 models, CHD testing is performed manually using a digital manual XY-stage. However, for the DUROLINE LV4, CHD testing is fully automated using the motorized XY-stage, providing a seamless and efficient testing process.

| LV1 | LV2 | LV4 | ||

|---|---|---|---|---|

| Hardness Scales | Vickers HV as per ISO 6507, ASTM E384, E92 | HV0,1 - HV0,2 - HV0,3 - HV0,5 - HV1 - HV2 - HV3 - HV5 - HV10 | ||

| Knoop HK as per ISO 4545, ASTM E384, E92 | HK0,1 - HK0,2 - HK0,3 - HK0,5 - HK1 - HK3 | |||

| Hardness conversions to other scales | As per ISO 18265 | |||

| Test Loads | Test Loads (gf) | 100gf, 200gf, 300gf, 500gf, 1kgf, 2kgf, 3kgf, 5kgf, 10kgf | ||

| Test Loads (N) | 0,9807N - 1,961N - 2,942N - 4,904N - 9,807N - 19,631N - 29,420N - 49,033N - 98,067N | |||

| Test Load Accuracy | "10gf - 200gf: +/- 1,5% and > 200gf: +/- 1,0% As per ISO standard (and ASTM E-384, JIS B7725, JIS B7734)" | |||

| Test Load Dwell Time | "from 5 - 99 sec with 1 sec increments As per ISO standard (and ASTM E-384, JIS B7725, JIS B7734)" | |||

| Test Load Application Speed | "10gf - 200gf: < 0.070 mm/s and > 200gf: < 0.200 mm/s As per ISO standard (and ASTM E-384, JIS B7725, JIS B7734)" | |||

| Load Force Application | Motorized force application with closed loop load cell control, Automatic load, dwell, unload | |||

| Load Selection | By N-Sure test settings | |||

| Turret | Turret Configuration | Motorized 3-mount turret: 1 indenter, 2 objectives Position Auto-indication | ||

| Indenter | Including 1 Vickers Diamond Indenter (ISO/DaKKs certified, Made in Germany) | |||

| Objectives | "Standard objectives 10X, 40X, optional 5X, 20X (Made in Germany) Image capture by integrated CCD-camera (no eyepiece)" | |||

| Optic System | Sample Image Capture | By Integrated CCD Camera, 5.0 MP, USB 3.0 (Made in Germany) | ||

| Indent Measurement Resolution | 0,00002 mm (0,02 μm) | |||

| Illumination | Illumination Source | Built-in LED Light Source | ||

| Automatic Brightness Control | Standard for highest contrast and sharpnes | |||

| Spindle | Z-axis (Spindle Vertical Movement) | Manual | Motorized | Motorized |

| Auto-Focus AF | Not Available | Standard | Standard | |

| "Motorized XY-Stage" | Motorized XY-Stage (for Fully Automatic Multiple Test & Measurements) | Not Available | Not Available | Standard |

| Travel Distance | Not Available | Not Available | 100x150 mm | |

| Controller System | Controller | "Built-in Windows operated mini-PC, communicates the hardness tester electronics by CANBUS Protocol" | ||

| Interface Network | Interface network USB (x4), Displayport (x2), LAN (x1) and Wireless LAN | |||

| Auxilliary | Optional Keyboard, Mouse (wireless) | |||

| Monitor | "External 22” Full HD Capacitive 10-point Multi-Touch Desktop Monitor, IPS Panel, Antistatic Shield, Tiltable, Integrated Power Adaptor" | |||

| User Interface | Operating System | Windows 10 | ||

| User Interface Software | N-Sure | |||

| Test Settings | Scale, Load Dwell Time , Start, Turret positioning, Hardness Conversion, Illumination, Screen preference settings, Alerts for errors | |||

| Measurement Settings | Surface Image capture, Indentation capture, Manual measurement and Auto-measurement, Single indents, Manual pattern, Preset pattern, CHD, EHT, NHT, GO/NG judgement, Statistics, Conversion, Cilindrical correction, Language, Database, Test Reports with image analysis data, Data export, User management, Service and Calibration Settings | |||

| Tester Body | Operational Environmental Conditions | "Ambient Operating Temperature Range: 23°C +/- 5°C Ambient Humidity Range: RH 40% to 70% relative humidity, non-condensing" | ||

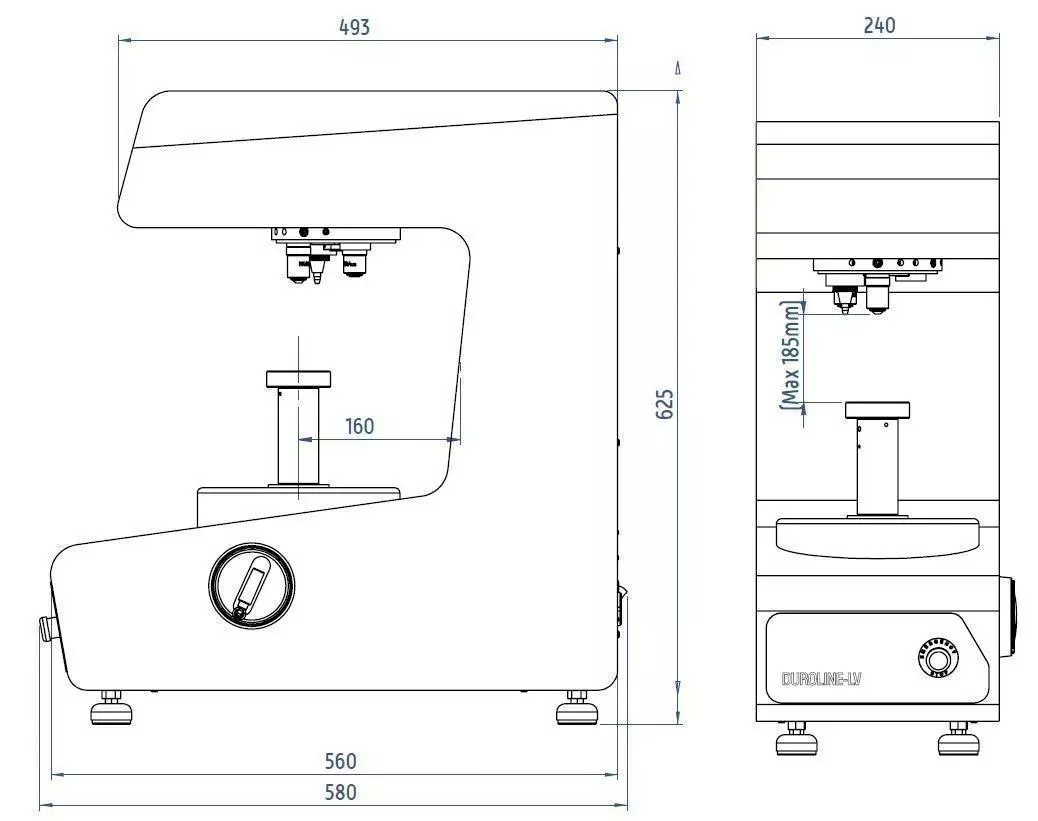

| Dimensions, WxDxH | 240x560x625 mm | |||

| Specimen Accommodation | Vertical 185 mm, Horizontal (throat depth) 160mm | |||

| Weight | 65 kgs | |||

| Mains | 100-240 V, 1-phase, 50/60 Hz, autosetting | |||

Accessories

Test stages

The DUROLINE LV-Series offers a wide range of accessories to accommodate various testing applications. The series features various stages and fixtures, including a basic manual XY-stage with either mechanical or digital micrometers and a motorized stage to accommodate single or multi-sample holders. Additionally, there are several clamping devices available to securely fix specimens of various geometries for quick and precise testing.

Object Lenses

The DUROLINE LV is equipped with 10x and 40x high-quality German-made object lenses for maximum image sharpness and clarity. Optional 5x and 20x objectives are also available to meet all testing needs.Test Blocks

To ensure accuracy and reliability, ISO/DaKKS-certified German-made test blocks are available for indirect verification of the tester.

Indenters

For even more accurate and reliable testing, ISO/DaKKS-certified German-made Vickers and Knoop indenters are available as options. These indenters have been rigorously tested and certified to meet the highest standards of accuracy and reliability, providing peace of mind during the testing process.