Vibratory Polisher for Metallography & Petrography

The Vibrapol is a vibratory polisher designed to prepare high quality polished surfaces on a wide variety of materials, such as; electron-backscatter diffraction (EBSD) applications, AFM (atomic force microscope), SEM (scanning electron microscopy) analysis, surface polishing on soft and ductile materials such as Titanium, Aluminium, pure Copper, Copper alloys, Aluminium alloys, Steel, Nickel-based alloys and Nano indentation or micro- hardness testing.

The high frequency vibration in horizontal motion produces a very effective polishing action to remove minor deformation remaining after mechanical preparation and reveal the stress-free surface. The Vibrapol is equipped with a variable frequency and voltage controller, this allows the operator to optimise the frequency and voltage independently depending upon specimen size and weight. The Vibrapol has a programmable timer for better control of the polishing process.

Features

- Low power consumption and noise design with piezoelectric vibratory plate, light weight but stable in operation

- Easily replacement design on disc, convenient to change and clean

- 7" LCD touch screen

- Save up to 20 customised programs

- Automatically adjust frequency setting

- It produces minimum surface deformations. Thus, it does not change the composition or structure of your sample’s surface.

- It is an inexpensive machine that can be maintained easily with low maintenance costs.

- Its versatile material handling also makes it feasible for multiple samples including Plastics, metals (both soft and hard), and ceramics.

Recommended Consumables for Vibrapol

| Product | Code | |

|---|---|---|

| CHEM-H polishing cloth (For final polishing with colloidal suspensions on medium to hard materials) | 300mm | 341784 |

| MRE polishing cloth (For final polishing with colloidal suspensions on soft materials) | 300mm | 341714 |

| NSH-B polishing cloth (For final polishing using alumina suspensions) | 300mm | 341203 |

| Colloidal silica, Col-K (NC) (For final polishing stage) | 1 Litre | 600261 |

| 5 Litres | 600199 | |

| Alumina suspension, 0-1 micron (For polishing steel & hard metals) | 1 Litre | 600711 |

| Alumina suspension, 0-0.7 micron (For polishing semi-hard metals) | 1 Litre | 600712 |

| Alumina suspension, 0-0.3 micron (For polishing soft metals) | 1 Litre | 600713 |

| Alumina suspension, 0-0.05 micron (For polishing soft materials) | 1 Litre | 343591 |

Technical Spec

| Description | Vibrapol 1200 |

|---|---|

| Bowl Size (mm) | Ø300mm / 12" |

| Power | 110 / 220V single-phase (50/60 Hz) |

| Rated Power | 50W |

| Dimension (WxDxH) | 516 x 503 x 379mm (cover opening: 607 x 503 x 669mm) |

| Weight(kg) | 53 |

| Sample holder sizes | 1" - 2", other sizes can be customised |

| Product Code | 370200 |

Importance, benefits and uses of Vibratory Polishing

This kind of polishing depends on the vibration against a polishing surface while using a polishing solution that can be any suspension providing lubrication and finishing at the same time. It creates a vibratory function that is continued until the sample loses its rough edges, bur, or any scale on the surface. The Vibrapol is specifically designed for surface finishing and polishing for multiple applications like metallography, optical microscopy, atomic force microscopy, SEM, and other techniques. The Vibrapol is easy to handle, use, maintain, cheaper and a perfect combination that can be used by both scientific researchers and industrial experts to finish the metallic samples before going through any kind of analysis.

Benefits of Vibratory Polishing

Vibrapol's use is not limited to sample preparation but it is one of the most viable and effective tools used for surface finishing. Becoming a major part of sample preparation for multiple structural analysis machines. Benefits of Vibrapol:

- Very easy to setup and use

- Depending on the type of sample, you can polish it easily within an hour or so and the results are consistent and reliable.

- It can process different materials ranging from steel, lead, aluminium, and magnesium. Thus, allowing diversity in its use. It is extensively used for soft metals as it does not incorporate any extra particles in the sample surface during polishing. No scratch, cut, or extra ion will be seen after using this machine for surface preparation.

- Minimal distortion in the sample surface is observed using the Vibrapol. Its gentle mode of working allows it to work on different surfaces' hardness on the same surface. It does not produce scaling or delamination. It smoothens the surface without changing surface components.

- Multiple part processing saves you time working on each sample separately.

- Programming the setup allows you to create an error-free program that is different for each kind of sample. The easy control panel allows you to set and do the polishing seamlessly, saving up to 20 programs to the machine for future use.

Sample Preparation ready for Scanning Electron Microscope (SEM))

We already know how important surface preparation, texture, and smoothness are when you see the surface of your metallic sample. Therefore, with the Vibrapol, you don't have to worry about minor flaws in sample preparation. Once you use this tool for sample preparation, you'll see how effective its use is. If we consider the phenomenon of SEM, we can see that an electron beam of nanometre scale falls on the surface of the sample. The beam is highly focused (made by using a collimator and then a set of lenses). This beam scans each portion of the sample to produce an accurate image. Thus, minor surface contaminations or variations can cause huge difficulty in the correct recording of sample structure. A perfect microanalysis is conducted when you have a finely polished surface by using the Vibrapol. View the images opposite for analysis example.

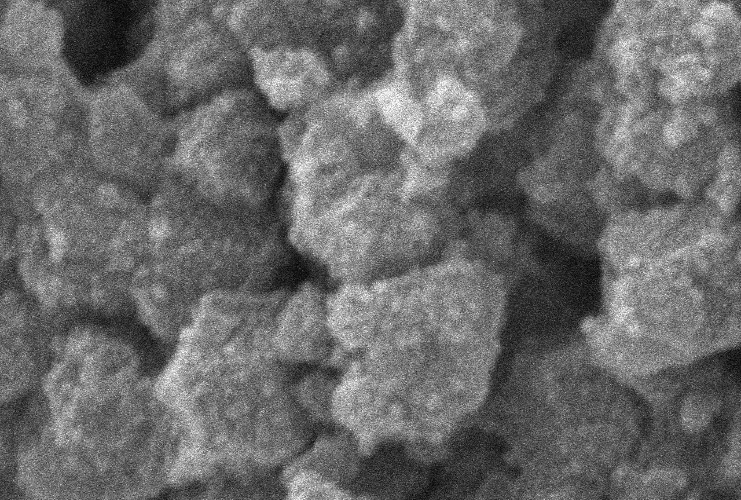

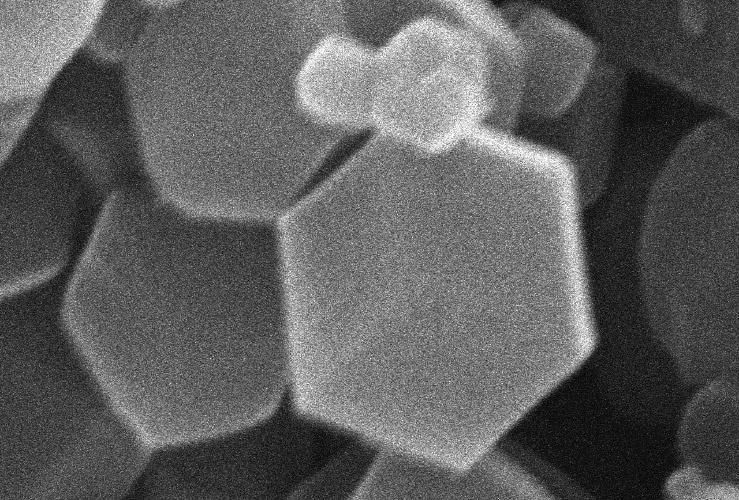

In this figure, a comparison of the electrode surface is presented that is sensitive to surface roughness to perform in an aqueous environment. It is done by using:

- The right surface finishing tool is a vibrator with a soft cloth and an alumina solution.

- Surface finishing is done for an hour with an interval of 10 to 15 minutes so the surface does not get damaged.

- Removing any excess alumina solution from the surface carefully and gently.

Figure 1: left (unpolished sample), right (polished sample)

Just by adding a correct process of sample preparation, you can see a huge difference in surface analysis. Now, it is showing a clear and perfect image of what the material surface looks like and what pattern its structure has. As we see in the first image, some impurities are hindering electron transmission from the surface. It is very important to prepare the metallic surface before you see it through the lens of your instrument. Thus, by considering the need for surface polishing, Vibrapol is a tool that must be included in your surface characterisation laboratory or institute.

Sample Preparation ready for Atomic Force Microscopy (AFM)

AFM is a surface monitoring technique that produces very precise images of the sample. Before AFM, it is necessary to polish the surface effectively after the mechanical preparation of the sample. For this purpose, Vibratory Polishing can serve as an excellent performing device. It allows the surface to be smooth at each point and even on the edges. It is because Vibratory Polishing gives almost the perfect horizontal vibrations that allow for debur and removal of any extra particle from the surface. The cantilever of AFM is just the size of an atom and thus, very fragile and delicate that even a small-sized impurity or irregularity in the surface can cause a huge loss by damaging the cantilever. Hence, to avoid such big losses Vibratory Polishing gives you a perfect polishing service for your samples.

Sample Preparation ready for Electron Backscatter Diffraction (EBSD)

If you're working with electron scattering, it is crucial to have your sample surface exceptionally smooth and flat. As the electrons strike the surface of the sample, they diffract in a particular direction depending on the surface properties. It needs the surface to be exceptionally smooth and flat so that each electron is diffracted at the right angle and subsequently produces high-quality images or results. The Vibrapol is designed to provide you with the accuracy that EBSD demands. By the vibratory motion of this machine, you can make any kind of metallic sample perfectly smooth and reliable for the detection of phase, its percentage, and related parameters. The perfection of your sample surface describes the quality of the image that you'll get from the machine. Moreover, these techniques are costly and nobody wants to lose the chance. So, use this Vibrapol to ensure the success of your results.

Sample Preparation ready for Optical Microscopy

Optical microscopy is one of the most popular techniques used in metallography. If you want to see and record the reliable structure of your material, it is crucial to make its surface very smooth, flat, and free of any impurities. By using Vibratory Polishing, you can do this easily. It is designed in a manner that creates a highly refined surface of the sample that will give you a perfect and clear microstructure. Minor details of the sample can be viewed as the surface is prepared well. Optical microscopy uses light beams to see the surface. Reflection of light from the surface is responsible for making an image and this reflection is based on the polishing of the sample surface. The better the polished surface, the better it is to make the image clear.