Rockwell Hardness Tester (Closed-Loop Controlled Automatic Hardness Testing)

DUROLINE R-Series are ideal instruments for quality assurance, quality control, research and metallurgical departments to monitor the hardness during fabrication and after heat treatment or welding as well as for the performance analysis on metal parts and new alloys. Common uses of this technique include evaluating the Rockwell hardness of metal components and steel alloys, regardless of whether they are in the form of small cut samples or large pieces, cylindrical or spherical parts, pipes, large rings, gears, crankshafts, or for conducting Jominy tests.

The DUROLINE R-Series Rockwell Hardness Tester is a reliable and accurate instrument for quality assurance and quality control in the manufacturing industry. It is widely used in metallurgical departments for monitoring the hardness of metal parts during fabrication, after heat treatment or welding, and for performance analysis of new alloys. This tester is capable of determining the Rockwell hardness of various steel alloys and metal components, including small cut samples, large pieces, cylindrical or spherical parts, pipes, large rings, gears, and crankshafts.

One of the key features of the DUROLINE R-Series is its versatile load range, which ranges from 3 kgf to 250 kgf. The closed-loop controlled load application by load cell technology ensures accurate and precise measurement. The tester comes with complete Rockwell and Superficial Rockwell test scales as well as Brinell Depth test scales up to 250 kgf. Its flexible Windows 10 based hardness test and measurement programme N-Sure allows for easy operation and data analysis. The database generates test results and reports, making it convenient for users to keep track of their measurements.

The user interface is a standout feature of the DUROLINE R-Series Rockwell Hardness Tester. It is equipped with an 11.6" HD 10-point multi-touch screen, making it easy to operate and navigate. The integrated Windows operated mini-PC with Intel and SSD specs provides a powerful computing platform for running the measurement programme and data analysis. The interface also includes a network of USB(x6), HDMI(x1), RS232(x2), LAN(x1), and Wireless LAN, providing users with a range of connectivity options.

The DUROLINE R-Series Rockwell Hardness Tester can accommodate large samples, and its very robust housing ensures precise measurements. Its new generation electronics and submicron precision depth measurement unit in full system integration allow for quick and accurate measurements. The tester is service-friendly, and its remote accessibility feature enables technicians to troubleshoot any issues without having to be physically present. The DUROLINE R-Series Rockwell Hardness Tester meets the latest ISO, ASTM, and JIS standards, ensuring that its measurements are accurate and reliable. Overall, this tester is an excellent investment for any manufacturing industry looking for an accurate and reliable instrument for quality assurance and quality control.

The DUROLINE R-Series is a newly developed automated indentation test and measurement system, designed by a team of international experts with extensive experience in hardness testing. This system is built using the latest available technology, with a focus on fast cycle time and high reproducible accuracy that meets international standards. The DUROLINE R-Series employs a smart and service-friendly synergy of a robust mechanical construction with load cell force control and integrated electronics system control using fast CANBUS technology and a high-quality Windows-based mini-pc. The hardness testing process is efficiently monitored through modern user interface technology, including 10-point multi-touch screen operation, supported by a fast and secure display connection. The DUROLINE R-Series is equipped with top-quality components and a high-performance mini-pc that guarantees solid and accurate performance for many years to come. Overall, the DUROLINE R Rockwell hardness tester series is highly functional and reliable, offering customers a superior solution for their indentation test and measurement needs.

Versatile load range from 3 kgf up to 250 kgf

The DUROLINE R is a highly versatile testing machine that offers a load range from 3 kgf up to 250 kgf, making it suitable for a wide range of applications. With this machine, users can perform the complete Rockwell and Superficial Rockwell test scales, which are commonly used in hardness testing of materials. In addition, the DUROLINE R also allows for Brinell Depth measurements up to 250 kgf test loads. This feature makes it possible to test and measure a wide range of materials with varying levels of hardness, ensuring that any specimen can be tested and measured within the applicable standards.

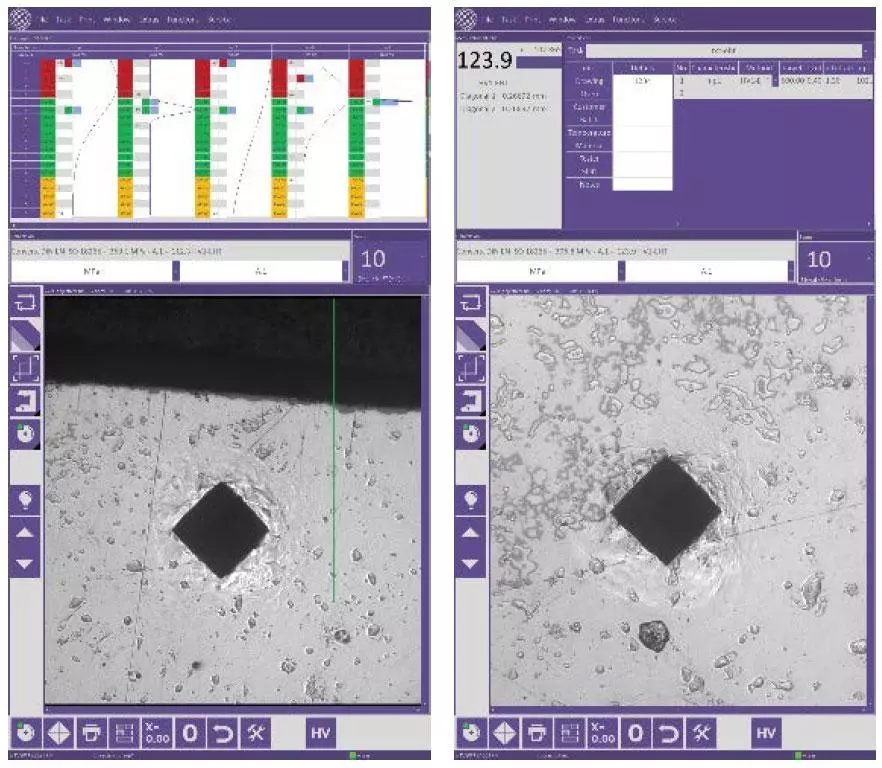

'N-Sure' Test and Measurement Software

The 'N-Sure' software programme is a highly versatile and efficient tool for automating the test and measurement process. With its flexible user interface, the programme offers increased productivity and operator efficiency by simplifying and streamlining testing procedures. The software can automate the test and measurement process as well as the optional motor-stage navigation process, ensuring that the application and removal of the test loads are performed fully automatically. This level of automation not only reduces testing time, but it also improves throughput and eliminates costly and time-consuming rework. Additionally, since the programme offers automatic preload, test start, and measurement capabilities, the repeatability of the testing process is excellent.

The software programme's automated preload application, main force application, indentation depth measurement, and hardness calculation are all performed automatically once the sample is clamped and the test cycle is initiated. In cases where the clamping nose is not used, the software will guide the operator to touch the indenter on the sample visually. Once the sample and indenter come into contact, the DUROLINE R will detect this and start the test cycle automatically. The programme eliminates the need for manual preload even with unclamped tests. If multiple measurements are required on the same or similar samples, the programme can recognise the previous contact position, thus eliminating the need to touch the indenter and sample again. The N-Sure software programme provides advanced database management of test results, report generation, and printing functions. In various industrial segments where testing the hardness results of critical components is a necessity, saving and retrieving measurement data is essential. The programme ensures that data is safely stored and presented in standard or customised reporting formats. With this software, generating test results and reports is both convenient and efficient.

Factory Certificated Direct and Indirect Calibration Report

All DUROLINE R-Series testers are calibrated according to DIN ISO 6508-2:2015 Rockwell hardness test standard.

Optional Diamond Cone Rockwell and Carbide Ball Rockwell/Brinell indenters

The DUROLINE R, certified by ISO/DaKKs (Made in Germany), offers the choice of diamond cone Rockwell and carbide ball Rockwell/Brinell indenters. It is compatible with Rockwell diamond cone indenters, Rockwell carbide ball indenters ranging from 1/16" to 1/2", and Brinell carbide ball indenters from 1 mm to 10 mm. With these indenters, all Rockwell and Superficial Rockwell test scales can be performed. In addition, Brinell Depth tests can be made up to 250 kgf test force.

Closed-Loop Controlled Load Application by Load Cell Technology

The DUROLINE R-Series testers are equipped with advanced closed-loop load cell technology that allows for precise and repeatable load application throughout a wide load range. This technology ensures that test loads are accurately applied without exceeding the target load threshold, providing maximum accuracy for all test loads.

High precision spindle

In addition to the load cell technology, the DUROLINE R-Series testers feature high-precision spindles that are designed to withstand the Rockwell test force and maintain zero displacement during force application. These spindles are constructed using high-quality components and design expertise to ensure long life and accurate results, even when testing large or heavy specimens.

Automatic Test Cycle

To streamline the testing process, the DUROLINE R-Series testers also feature an automatic test cycle for Rockwell hardness testing. This cycle includes preload application, main load application, and depth measurement, all of which are performed automatically. This automation ensures quick and simple tests with maximum repeatability, making the testing process more efficient and reliable.

| DUROLINE R1 | ||

|---|---|---|

| Hardness Scales | Rockwell Regular Scales as per ISO 6508 & ASTM E18 | HRA, HRBW, HRC, HRD, HREW, HRFW, HRGW, HRHW, HRKW |

| Rockwell Regular Scales as per ASTM E18 | HRLW, HRMW, HRPW, HRRW, HRSW, HRVW | |

| Rockwell Superficial Scales as per ISO 6508 & ASTM E18 | HR15N, HR30N, HR45N, HR15TW, HR30TW, HR45TW | |

| Rockwell Superficial Scales as per ASTM E18 | HR15WW, HR30WW, HR45WW, HR15XW, HR30XW, HR45XW, HR15YW, HR30YW, HR45YW | |

| Brinell Depth Scales | HBT 1/5 to 10/250 | |

| Test Loads | Preload for Superficial Rockwell (kgf) | 3 kgf |

| Preload for Rockwell (kgf) | 10 kgf | |

| Test Loads for Superficial Rockwell (kgf) | 15 kfg, 30 kgf, 45 kgf | |

| Test Loads for Rockwell (kgf) | 60kfg, 100kgf, 150kgf | |

| Test Loads for Brinell Depth (kgf) | 5 kgf to 250 kgf | |

| Test Load Accuracy | As per ISO 6508 and ASTM E18 | |

| Load Force Application | Motorised force application with closed loop load cell control, Automatic preload, Automatic main load, dwell, unload | |

| Load Selection | N-Sure test settings | |

| Indenters | Indenters for Rockwell Hardness Testing | Rockwell diamond cone indenter (ISO/DaKKs Certified, Made in Germany) Rockwell carbide ball indenter 1/16" (ISO/DaKKs Certified, Made in Germany) Rockwell carbide ball indenter 1/8" (ISO/DaKKs Certified, Made in Germany) Rockwell carbide ball indenter 1/4" (ISO/DaKKs Certified, Made in Germany) Rockwell carbide ball indenter 1/2" (ISO/DaKKs Certified, Made in Germany) |

| Indenters for Brinell Depth Hardness Testing | Brinell carbide ball indenter 1 mm (ISO/DaKKs Certified, Made in Germany) Brinell carbide ball indenter 2.5 mm (ISO/DaKKs Certified, Made in Germany) Brinell carbide ball indenter 5 mm (ISO/DaKKs Certified, Made in Germany) Brinell carbide ball indenter 10 mm (ISO/DaKKs Certifivated, Made in Germany) | |

| Controller System | Controller | USB(x6), HDMI(x1), RS232(x2), LAN(x1) and Wireless LAN |

| Interface Network | Optional Keyboard, Mouse (wireless) | |

| Auxilliary | Windows 10 | |

| User Interface | Operating System | N-Sure |

| User Interface Software | "Ambient Operating Temperature Range: 23°C +/- 5°C | |

| Tester Body | Operational Environmental Conditions | Ambient Humidity Range: RH 40% to 70% relative humidity, non-condensing" |

| Dimensions, WxDxH | 200 x 535 x 804 mm | |

| Specimen Accomodation | Vertical 248 mm, Horizontal (throat depth) 181 mm | |

| Weight | 132 kgs | |

| Mains | 100-240 V, 1-phase, 50/60 Hz, autosetting | |

The DUROLINE R-Series testers offer a wide range of accessories that can be customised to fit any application. One of the most versatile accessories available for these testers is the test stage. The test stage can be equipped with various test tables that are designed to accommodate different sample types, including small cut samples, large pieces, cylindrical or spherical parts, pipes, large rings, gears, and crankshafts. This means that the DUROLINE R-Series testers can be used to test a wide variety of materials, from small, delicate samples to large and heavy industrial components. In addition to the test stages, the DUROLINE R-Series testers also come with a standard clamping nose on the test head that can securely fix many different types of samples, ensuring accurate and repeatable results.

For indirect verification of tester accuracy, German-made test blocks that are ISO/DaKKS certified are available as an optional accessory. These test blocks are designed to provide a reliable reference point for ensuring the accuracy and consistency of the tester over time. Finally, ISO/DaKKS certified German-made Rockwell and Brinell indenters are available as an optional accessory for testing any Rockwell/Superficial Rockwell scales and Brinell depth scales up to 250 kgf. These high-quality indenters are designed to ensure accurate and repeatable results, even when testing the toughest materials. Overall, the accessories available for the DUROLINE R-Series testers make them highly versatile and adaptable to any testing application, ensuring accurate and reliable results every time.