Polishing Consumables for Materials Science

Polishing consumables are a critical component in the preparation of materials for examination in the field of materials science. The use of proper polishing consumables can significantly impact the quality and accuracy of the analysis.

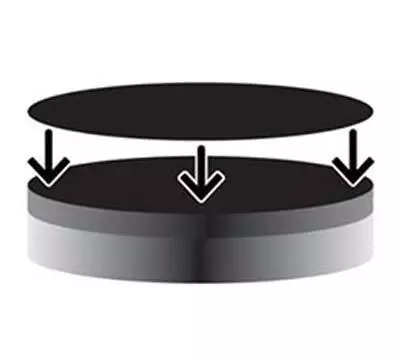

Polishing cloths are a commonly used consumable in materials science. They are used to remove any rough or irregular surfaces on a material specimen, leaving it with a smooth and even surface. The type of polishing cloth used will depend on the type of material being prepared, as well as the desired level of finish. For example, diamond polishing cloths are used for polishing hard materials, such as ceramics, while cotton polishing cloths are used for softer materials, such as metals.

Polishing compounds are abrasive substances that are used in conjunction with polishing cloths to remove surface irregularities from a material specimen. They are available in a variety of grades and types, depending on the material being polished and the desired level of finish. For example, aluminum oxide and silicon carbide polishing compounds are commonly used for polishing ceramics, while diamond polishing compounds are used for polishing hard metals.

Polishing suspensions are suspensions of abrasive particles in a liquid. They are used in conjunction with polishing cloths to polish material specimens. The type of polishing suspension used will depend on the type of material being prepared and the desired level of finish. For example, diamond suspensions are commonly used for polishing hard materials, while alumina suspensions are used for polishing softer materials.