Fully Automatic Programmable Grinding/Polishing System (operator free)

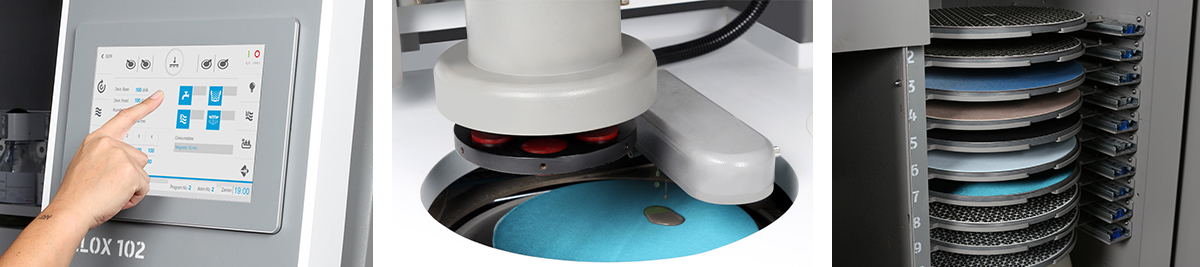

The VELOX 102 Fully Automatic Programmable Grinding/Polishing System has been engineered to facilitate sample preparation without the need for operator involvement, ensuring high-volume sample throughput from Planar Grinding to Fine Grinding/Polishing, Fine Polishing, Cleaning, and Drying. Simply place the sample holders in the auto-feed system, select the appropriate program for your specific application, and press the "Start" button. The system will autonomously prepare your samples for analysis. Furthermore, it can queue up to six sample holders during operation, allowing for uninterrupted sample preparation.

The VELOX 102 Automatic Programmable Grinding and Polishing System boasts a compact design, including the following features:

- Planar grinding station

- Fine grinding/polishing station

- A fully automatic sample cleaning and drying station

- A fast automatic grinding/polishing disc replacement system

- An automatic sample holder replacement and feeding system

- An automatic peristaltic dosing unit

The Planar Grinding Station is equipped with a robust 4 kW motor that offers adjustable variable wheel speed ranging from 500 RPM to 1500 RPM with a soft start-stop function, enabling rapid planar grinding of specimen surfaces. It accommodates 300 mm diameter flat grinding stones, and the automatic dressing unit ensures a high material removal rate and maximum flatness on the sample.

The Fine Grinding/Polishing Station features a powerful 1.1 kW motor with an adjustable variable wheel speed from 50 to 600 RPM, also with a soft start-stop function. It accommodates 250 mm grinding/polishing discs, with an automatic disc cleaning feature to keep the discs ready for the next use.

The Fully Automatic Sample Cleaning and Drying Station can conduct pressurised water cleaning, ethanol cleaning, ultrasonic cleaning, and fast drying with filtered air, programmable for each grinding/polishing step with the same or different parameters.

The system incorporates an Automatic Grinding/Polishing Disc Exchange System, capable of storing up to ten different grinding/polishing discs. During the cleaning operation, the system automatically switches discs according to the selected preparation recipe, with automatic notifications when a disc reaches the end of its life cycle.

The user-friendly HMI touch screen enhances productivity, sample consistency, and operator comfort. All preparation parameters can be stored in memory under specific program numbers, allowing for easy recall and operation without operator intervention. Additionally, a library of 20 preparation programs can be saved with related specimen names or numbers, and an acoustic signal indicates cycle completion. Benefits of the VELOX 102 include its compact design, operator-free sample preparation, non-stop sample preparation, fast processing, precise sample surfaces, repeatable results, cost-effectiveness, safety, and reliability. It is designed for 24/7 operation and low maintenance, ensuring long-lasting and dependable performance.

The Automatic Sample Holder Replacement & Feeding System can store and queue up to six specimen holders, each programmable with the same or different grinding/polishing parameters. The sample holder is automatically retrieved from the rack for the grinding/polishing operation, and the next sample holder is loaded without any operator intervention. Completed sample holders can be removed during the operation, ensuring non-stop sample preparation for high sample throughput.

The Automatic Head, driven by a servo motor, progresses through each step automatically, ensuring accuracy and reproducibility. It can apply adjustable "Central" force pneumatically, from 30 N to 750 N, with an in-built encoder for measuring material removal. The automatic head also features a high-torque 350 W motor with adjustable variable speed from 50 RPM to 200 RPM. It can accommodate Ø160 mm sample holders.

The VELOX 102 is equipped with an Automatic Peristaltic Dosing System, comprising eight peristaltic pumps (six for diamond suspensions/lubricant and two for aluminium oxide suspensions). This system ensures consistent specimens and minimises the consumption of time and materials. Dispensing parameters are controllable via the LCD screen.

| Model | VELOX 102 |

|---|---|

| Planar Grinding Station | Standard |

| Fine Grinding/Polishing Station | Standard |

| Automatic Sample Cleaning and Drying Station | Standard |

| Automatic Disc Replacement System | Standard |

| Automatic Peristaltic Dosing Unit | Standard |

| Automatic Sample Holder Replacement & Feeding System | Standard |

| Planar Grinding Motor Power (S1) | 4 kW |

| Grinding Stone Speed | 500 - 1500 RPM |

| Grinding Stone Rotation Direction | CCW |

| Grinding Stone Diameter | Ø300 mm |

| Grinding Stone Cleaning & Drying | Automatic |

| Automatic Dressing System | Standard |

| Dressing Tip | Diamond |

| Dressing Depth | 10 µm - 100 µm |

| Dressing Period | 20 s - 600 s |

| Fine Grinding/Polishing Motor Power (S1) | 1.1 kW |

| Grinding/Polishing Disc Speed | 50-600 RPM |

| Grinding/Polishing Disc Rotation Direction | CCW |

| Grinding/Polishing Disc Diameter | Ø250 mm |

| Grinding/Polishing Disc Cleaning & Drying | Automatic |

| Automatic Disc Replacement System | Standard with 10 Discs Capacity |

| Grinding/Polishing Dics Life Monitor | Standard |

| Automatic Head Motor Power | 350 Watt |

| Automatic Head Motor Speed | 50-200 RPM |

| Automatic Head Motor Rotation Direction | CW/CCW |

| Grinding Depth Measurement | Standard |

| Grinding Depth Range | 0 - 5 mm |

| Sample Holder Type | Central Force |

| Sample Holder Diameter | Ø160 mm |

| Central Pressure Force | 30 - 750 N |

| Sample Cleaning | Pressurised Water + Ethanol + Ultrasonic |

| Sample Drying | Filtered Pressurised Air Drier |

| Automatic Peristaltic Dosing Unit | Standard with 8 Individual Pumps |

| Magnetic Stirrers | Standard |

| HMI Touch Screen | 9.7" Coloured Touch Screen |

| Program Memory | 20 Programs |

| Dimensions, WxDxH | 2045x902x1690h mm |

| Weight | 850 kgs |

| Mains | 400 V, 3 phase, 50/60 Hz. |