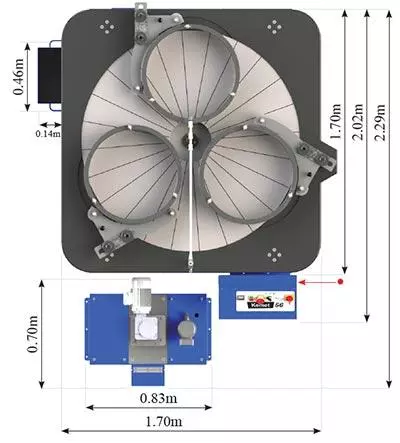

Large Lapping Table - Kemet 56

The Kemet 56 is equipped with a 1422mm diameter lap plate. This is manufactured from Grade 300 grey cast iron to ISO 185(2005). It consists of individual segments bolted to a support plate. Outlets are provided to feed each conditioning ring via a track wire, with individual control valves. This system is designed so that a circulatory flow is established. The pump is capable of delivering far more compound to the outlets than is necessary. Excess compound is returned to the reservoir via a sloping drain tube. This together with the constant agitations provided by the stirrer minimises the tendency of the abrasive grains to settle out in the vehicle.

The machine is intended for use with free abrasive compounds. A dispensing system, for use with water and diamond compounds etc., can also be fitted. Flatness of the machines lap plate, and consequently of the work, is controlled by adjusting the position of the conditioning rings relative to the lap plate track. The lapping plate drive system uses a separate motor and worm & wheel mechanical reduction gearbox with multi-belt drive., and is mounted in a floor standing base. This base is a fabricated steel channel framework with removable panels for ease of access during maintenance. The drive system incorporates an electronic soft start which will smoothly accelerate the lap plate from standstill to full speed over a controlled time period. This is preset, though can be adjusted if required, to suit particular process conditions. This machine is also available in a pneumatic lift version. See appropriate datasheet, available on request.

- Heavy duty floor standing base with integrally mounted drive motor, reduction gearbox, abrasive distribution system, complete with control panel.

- Heavy duty work table, vertically adjustable.

- Three conditioning rings, with adjustable, sealed roller bearing yoke assemblies to maintain lap flatness.

- Free standing abrasive system complete with pump and driven stirrer tank with multiple point distribution.

- High torque drive unit consisting of 11kW motor and reduction gearbox. Lap plate speed 48 rpm.

- Operator controls at 110V, complies with EN 60 204.

- CE compliant.

- Soft start to main drive motor.

- Operator panel with start / stop controls, and multiple range digital process timer.

- Waste tank.

Optional Features

- Four ring model.

- Pneumatic lift version.

- Electronic variable speed drive,

- Water cooled lap plate.

- Non-standard voltages.

- Stainless steel wetted parts.

- Peristaltic pump.

- Corporate colours.

- Fixed guarding.

| Technical Spec | Open Face | Pneumatic Lift |

|---|---|---|

| Height (H) | 1030mm | 2260 mm |

| Working Height (WH) | - | 1400 mm |

| Width (W) | 1700 mm | 1700 mm |

| Depth (D) | 2020 mm | 2520 mm |

| Approx. Weight | 4100kg | 5000kg |

| Lapping Plate outside Diameter | 1422 mm | 1422 mm |

| Lapping Plate Speed | 48 rpm | 48 rpm |

| Conditioning Ring inside Diameter | 3 x 578 mm | 3 x 578 mm |

| 4 x 530 mm | 4 x 530 mm | |

| Max load per Conditioning ring | 3 ring 400Kg | 3 ring 400Kg |

| 4 ring 350Kg | 4 ring 350Kg | |

| Main Drive Motor | 11kW | 11kW |

| Abrasive pump motor | 0.18kW | 0.18kW |

| Abrasive Tank capacity | 115 Litres | 115 Litres |

| Waste tank capacity | 37 Litres | 37 Litres |

| Standard Electrical Supply | 220V or 380V or 415V 3 Ph 50Hz | |