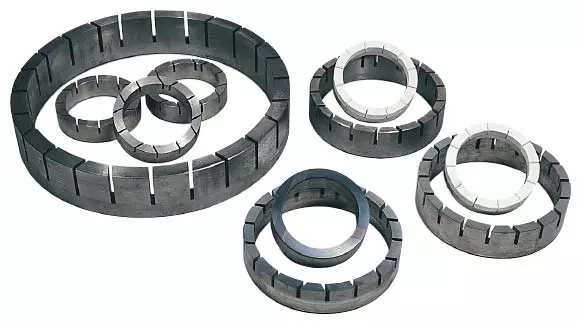

Conditioning Rings

Cast iron conditioning rings are designed to wear down naturally during the lapping process, ensuring consistent performance and precision. Over time, these rings may need replacement, and we offer a wide range of replacement options compatible with most flat lapping machine models. They are available in two designs: solid and serrated, allowing users to select the most suitable configuration for their specific applications.

For more specialised needs, we provide custom-built diamond-plated conditioning rings. These rings are available in a variety of grit sizes to match your exact requirements, including popular options such as Grit 60 and Grit 120. Their robust diamond coating ensures durability and effective performance in demanding lapping operations. In addition to these, we also offer plastic-faced and ceramic-faced conditioning rings, which are specifically designed for polishing rather than traditional lapping. These alternatives are ideal for applications that require a finer, smoother finish.

Cast Iron Conditioning Rings

| Lapping Machine | 3 Ring | 4 Ring |

|---|---|---|

| Kemet 15 | 360203 | - |

| Kemet 20 | 361027 | - |

| Kemet 24 | 360208 | 360274 |

| Kemet 36 | 360278 | 360682 |

| Kemet 40 | 360683 | * |

| Kemet 48 | 360833 | 360642 |

* Available on request

Ceramic Faced Conditioning Rings

| Lapping Machine | Ceramic Faced Conditioning Ring Dimensions | Code |

|---|---|---|

| Kemet 15 | OD: 178mm, ID: 140mm, Height of ceramic: 20mm | 361522 |

| Kemet 20 | OD: 231mm, ID: 191mm, Height of ceramic: 30mm | 361982 |

| Kemet 24 | OD: 286mm, ID: 248mm, Height of ceramic: 30mm | 361528 |

| Kemet 36 | OD: 419mm, ID: 368mm, Height of ceramic: 38mm | E03547 |

Plastic Faced Conditioning Rings

| Lapping Machine | Plastic Faced Conditioning Ring Inside Dimension | Code |

|---|---|---|

| Kemet 300L2 | 125mm | 345454 |

| Kemet 15 | 140mm | 361399 |

| Kemet 20 | 191mm | 362736 |

| Kemet 24 | 248mm | 361665 |

| Kemet 36 | 368mm | 361981 |

Other Sizes are available upon request.

Cleaning conditioning rings using Kemet ultrasonic cleaners

Occasionally with the conditioning rings it’s important to give them a clean especially when they start to become contaminated or blocked and if you are changing grades from a coarse grade to a fine grade.

So in between the grooves we have contamination and if a coarse grade is used it will be embedded in the surface, so we are going to show you the best way of cleaning these and getting back to a fresh clean control ring.

What we have here is a ultrasonic cleaner system. In this unit we use water with a concentrated chemical, in this instance we are using Kemet Type A, which is an alkaline detergent which is good for general use on all types of steels and ferrous materials, the concentration in the system is about 12-15% and the temperature is 50-55°C.

So put the control ring into the system with the slots facing downwards, we are going to give this a process for 10 minutes and then turn the ring over for another 10 minutes. Sometimes it is a good idea to move the basket up and down to loosen the contamination and fluid. After a short period, you will see most of the contamination has cleared, but leave in for the full 10 minutes. For a badly contaminated control ring use a brush to remove any loose contamination, and then put the control ring back in but the other side up and start the process again.

After the second process the ring should be clean, next stage is to rinse. It is important to rinse the ring after the process, what rinsing does is removing the concentrated detergent and any loose contamination and will also give you a chance to inspect it is completely clean. If you use warm water, it will help to speed up the drying process.

One important thing to check is the chamfer on the outside, this will gradually wear away, once the chamfer disappears, it is important to re-machine on roughly about 3mm by 45 degrees. You can also look at the condition of the ring width ways because that will very gradually wear down, when it gets down to the point that the grooves start to disappear, that’s the time to replace the ring because not only has it lost its effectiveness but also a lot of its weight for conditioning the plate.