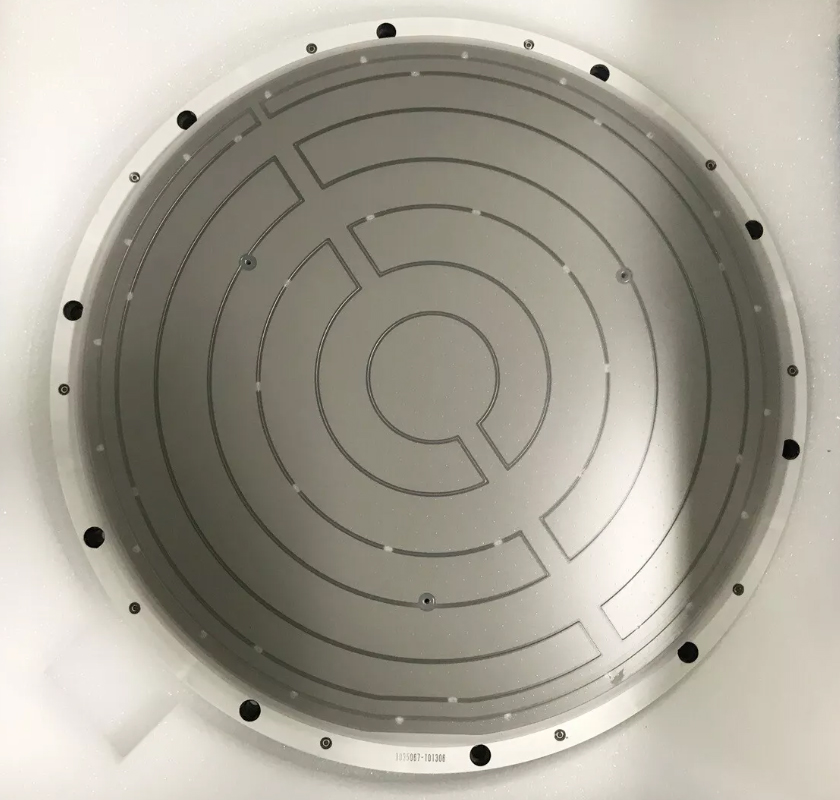

Ceramic Chuck or Electrostatic Chuck (ESC/e-Chuck) Lapping and Surface Refinishing

Kemet specialises in the precision refinishing of ESCs, providing a range of services tailored to meet diverse application needs. Whether addressing wear and tear, manufacturing defects, or altering the geometry of a new chuck, Kemet’s capabilities ensure optimal performance and extended lifespan of your ESCs.

Electrostatic chucks often require specific surface profiles to suit unique operational demands. Kemet can reshape ESC surfaces to achieve:

- Flat profiles with tolerances as tight as ±1/4 micron.

- Concave profiles from 1/4 micron up to 2 microns.

- Convex profiles with comparable precision to concave designs.

- These refinements are ideal for ensuring uniform wafer contact and minimising processing inconsistencies in high-precision applications.

ESCs are constructed from advanced materials designed to withstand the challenges of high-temperature, high-vacuum environments and chemical exposure. Kemet excels in working with a diverse range of dielectric materials, including polyimide, alumina (Al₂O₃), sapphire, silicon carbide, epoxy, silicon nitride, SiSiC (silicon-silicon carbide), glass, and thermal spray coatings. The ability to refine and process these materials to nanometre-level precision is a cornerstone of Kemet’s refinishing services, ensuring exceptional quality and performance in every project.

Kemet employs advanced lapping and polishing techniques to achieve the desired surface finish. These methods not only restore the chuck’s surface but also improve its performance by enhancing flatness, reducing surface roughness, and removing any defects. Lapped surfaces offer high precision and consistency, while polished finishes are ideal for applications demanding minimal surface irregularities.

For customers requiring defect removal or slight shape adjustments, Kemet’s expertise in minimal material removal ensures the preservation of the ESC’s structural integrity. Material removal as low as 1/4 micron can effectively address surface imperfections without compromising performance.

Refinishing and reshaping services provided by Kemet cater to a wide spectrum of industries and applications:

- Wafer Handling: Ensures secure and distortion-free contact for delicate wafers.

- Inspection and Metrology: Enhances measurement accuracy by maintaining surface precision.

- Display Manufacturing: Improves uniformity for thin-film processes in OLED and LCD fabrication.

- Metal Deposition and Etching: Optimises substrate placement for deposition or etching uniformity.

Why Choose Kemet?

Kemet’s decades of experience and commitment to precision make it a trusted partner for ESC refinishing and reshaping. The company’s advanced techniques, combined with deep material expertise, ensure that your chucks are not only restored but also optimised for peak performance. Whether refurbishing used chucks or customising new ones, Kemet delivers solutions that align with the most rigorous industry standards.

Understanding Electrostatic Chucks

Electrostatic chucks (ESC or e-chucks) play a vital role in semiconductor manufacturing, wafer handling, and various other precision applications. These components are critical for holding wafers, substrates, or thin films securely in place during processes that demand nanometer-level accuracy. Over time, or during initial production, these chucks may require refinishing or reshaping to meet stringent performance standards. Kemet, with over 80 years in the precision finishing industry, offers state-of-the-art solutions for restoring, reshaping, and customising electrostatic chucks to meet the most demanding specifications.

Electrostatic chucks leverage electrostatic forces to hold substrates in place without requiring physical clamping. They are typically constructed with a dielectric layer, which serves as the insulating medium, and a conductive layer beneath that facilitates the generation of electrostatic charge. These chucks are widely used in processes such as:

- Dry Etching: Providing a stable base for precise material removal.

- Ion Implantation: Securing wafers for uniform doping processes.

- Lithography: Maintaining flatness for accurate imaging.

- Bonding Technology: Facilitating reliable adhesion in microelectronics assembly.

- Given their pivotal role in these and other applications, ESCs must maintain exceptional flatness, precise geometry, and surface integrity.

Electrostatic chucks are indispensable in high-precision manufacturing, and their performance is closely tied to their surface condition. Through expert refinishing, reshaping, and customisation services, Kemet ensures that ESCs meet and exceed the demands of modern industrial applications. By restoring flatness, addressing defects, and tailoring surface profiles, Kemet enhances the reliability and efficiency of these critical components, supporting the success of your manufacturing processes. For more information or to discuss your specific ESC refinishing needs, contact Kemet today.