CNC Self-Adjusting Sleeves and Floating Holders

XEBEC Self-Adjusting Sleeve™

Predetermined brush length is automatically projected and assists unmanned operation. Effective to eliminate human error, maintain optimal machining conditions and consistent machining quality.

Target - XEBEC Brush Surface™ (ø6~40)

| Product code | Target brush (Product code) | Outermost diameter Dc (mm) | Shank diameter Ds (mm) | Overall length L(mm) | Shank length ls (mm) | Main body weight (g) | Maximum rotational speed (min-1) |

|---|---|---|---|---|---|---|---|

| XP- AUT06M | A13-CB06M | ø 37 | ø 10 | 12 4.1 | 35 | 220 | 100 00 |

| A11-CB06M | |||||||

| A21-CB 06M | |||||||

| A32-CB06M | |||||||

| XP- AUT15 M | A13-CB15M | ø 37 | ø 10 | 136 .3 | 35 | 270 | 6000 |

| A11-CB15M | |||||||

| A21-C815M | |||||||

| A32-CB15M | |||||||

| XP- AU T25M | A11-CB25M | ø 60 | ø 16 | 18 9 | 41. 5 | 795 | 5000 |

| A21-C825M | |||||||

| A32-CB25M | |||||||

| XP- AUT40M | A11-CB40M | ø 60 | ø 16 | 189 | 41.5 | 910 | 3000 |

| A21-CB40M | |||||||

| A32-CB40M |

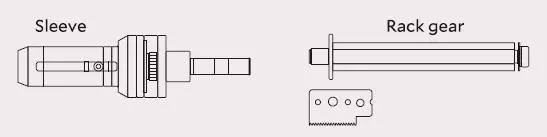

Tool schematic - It consists of a sleeve and a rack gear. XEBEC Brush Surface is not included.

Applicable equipment - The tool can be mounted on a machine which enables to stop and hold the sleeve at the fixed position.

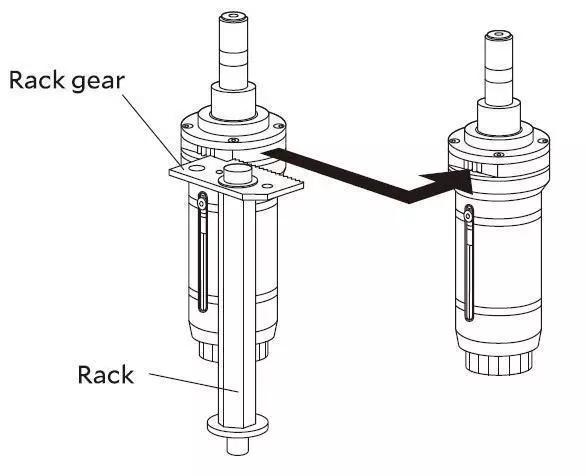

How to use Self-Adjusting Sleeve

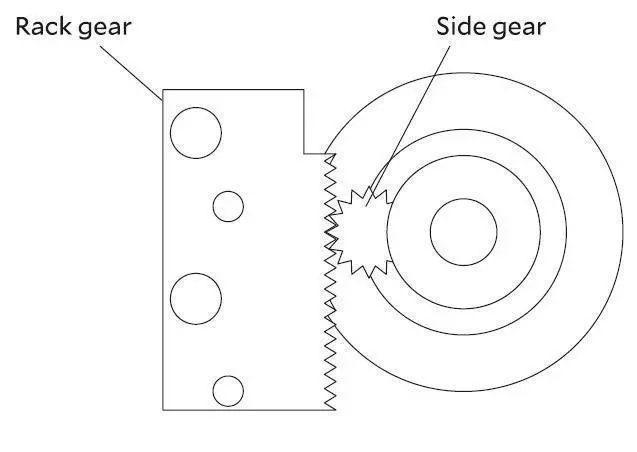

Mechanism - Predetermined brush length is automatically projected when the embedded side gear passes the rack gear which is mounted in a machine.

Operation Image

Pass the side gear of main body through the rack gear as shown above.

Mesh the side gear of main body and the rack gear.

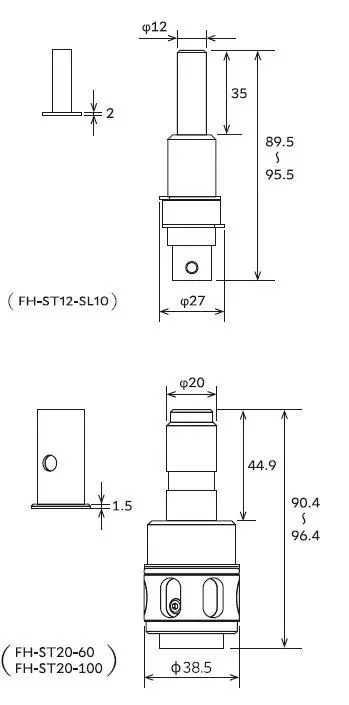

XEBEC Floating Holder™ Straight shank type

The built-in spring enables stable load, contributing to consistent edge quality and reduce the frequency to adjust the depth of cut.

Target - XEBEC Brush Surface™ (ø6~100)

Applicable equipment

| Product code | Target brush diameter (mm) | Diameter for the sleeve shank (mm) | Maximum rotational speed (min-1) | Accessories |

|---|---|---|---|---|

| FH-ST12 -SL10 | ø 6 | ø 6 (with the supplied bush 1) | 10000 | 1. ø 6 bush |

| 2. ø 8 bush | ||||

| ø 15 | ø 6 (with the supplied bush 2) | 6000 | ||

| 3. Low pressure spring | ||||

| ø 25 | ø 8 (with the supplied bush 3) | 5000 | 4. Standard spring* | |

| 5. High-pressure spring | ||||

| *Installed when shipped | ||||

| ø 40 | ø 10 | 3000 | ||

| FH-ST2 0-60 | ø 60 | ø 12 | 2000 | ø 12 bush |

| FH-ST20-100 | ø 100 | ø 16 | 1200 | ø 16 bush |

* Optional maximum pressure. spring is available.

Precautions for Use

- Approach the tool vertically when making it engaged with workpiece.

- It can not be used if there are intermittent machining or protrusions.

- Using on horizontal machining center, it may not function when spring load is low.

XEBEC Floating Holder™ BT shank type

The built-in spring enables stable load, contributing to consistent edge quality and reduce the frequency to adjust the depth of cut.

Target - XEBEC Brush Surface™ (ø6~25)

Applicable equipment

| Product code | Target Brush diameter(mm) | Diameter for the sleeve shank (mm) | Maximum rotational speed (min-1) | length undergauge line (mm) |

|---|---|---|---|---|

| FH- BT3 0 | ø 6 | ø 6* | 10000 | 75 |

| ø 15 | ø 6* | 6000 | ||

| ø 25 | ø 8 | 5000 | ||

| FH-8T4 0 | ø 6 | ø 6* | 10000 | 60 |

| ø 15 | ø 6* | 6000 | ||

| ø 25 | ø 8 | 5000 |

* Optional ø 6 bush is available. Please contact for the details.

Precautions for Use

- Approach the tool vertically when making it engaged with workpiece.

- It can not be used if there are intermittent machining or protrusions.

- Using on horizontal machining center, it may not function when spring load is low.

How to use Floating Holders

Approach the Brush vertically when making it engaged with a workpiece. Don't contact the side of the Brush because it will cause damage to the bristles.

- Approach the tool from above to the workpiece while not in motion.

- Set the depth of cut and make the spring contracted.

- Rotate the tool and start feeding.

- Stop rotation and feeding of the tool when machining is completed.

- Remove the tool upward

Spring load

FH-ST12-SL 10

| Spring type | Outer diameter (mm) | Spring constant (N/mm ) | Overall length (mm) | Load by stroke (N) | ||

|---|---|---|---|---|---|---|

| 0 mm | 6 mm | |||||

| Standard spring | Installed | ø 10 | 0.3 | 40 | 4.5 | 6.3 |

| Low - pressure spring | Attachment | ø 10 | 0.3 | 30 | 1.5 | 3.3 |

| High - pressure spring | Attachment | ø 10 | 0.55 | 39 | 7.2 | 10.5 |

| Maximum load spring | Sold separately | ø 10 | 3.03 | 30 | 15.2 | 33.4 |

FH-BT30/40

| Load adjustment | Loadby stroke(N) | Adjustment Screw Position | |

|---|---|---|---|

| 0 mm | 6 mm | ||

| Standard Float | 2 | 6 | Whenload adjustment screw 2 is at the end of the shaft. |

| Higher Float | 6 | 10 | Whenload adjustment screw 2 is at the back of the shaft. |

Maintenance

If the floating function doesn't work smoothly, sludge may have entered the tool. Disassemble the tool and clean the inside. Regular maintenance is recommended. See the instruction manual for the details. Lithium soap grease is recommended.

XEBEC Short BT Holder™

Compact tool holder whose length under the gage line is 23.5mm (including bush flange thickness 1.5mm). Effective where tool length is restricted.

| Product code | Target shank diameter (mm) |

|---|---|

| SH-BT30 | ø 20 |

Target

XEBEC Brush Surface™

XEBEC Self-Adjusting Sleeve™

XEBEC Floating Holder™

Applicable equipment

XEBEC Brush Length Adjustment Tool™

Jig for quick in-machine brush length adjustment.

Target - XEBEC Brush Surface™ (ø 15-100)

| Product code | Corresponding Brush diameter (mm ) | Size of built-in hexagonal wrench (mm ) |

|---|---|---|

| XP- EZ-0 01 | ø 15 / ø 5 / ø 40 / ø 60 / ø 100 | 1.5 2.0 |

How to use

- Move the brush rest using the adjustment knob to set the amount of brush projection.

- Tighten the fixing nut.

- Hold the unit in one hand, and align the sleeve rest with sleeve tip.

- Loosen the screws to allow the brush to drop to the brush rest.

- Tighten the screws to secure the Brush in place.