Surface Finishing Titanium

Scope of Work: To mirror polish 3 x 100mm diameter titanium wafers both sides and 3 x on one side, to a surface Ra better than 0.01 µm

Stage 1. Lapping process - Equipment used:

- Kemet lapping/polishing machine

- Cast Iron lapping plate

- Kemet Flatness gauge

- Kemox 0-800S

Stage 2. Semi polishing process - Equipment used:

- Kemet lapping/polishing machine

- Cast Iron lapping plate

- ASFL polishing cloth, 15” diameter

- Kemet Liquid diamond 3 micron type K diamond slurry

- Plastic faced control ring

Stage 3. CMP process - Equipment used:

- Kemet KemCol machine

- Chem –H pad, 15” diameter

- Col- k (NC)

- Plastic faced control ring

Lapping process breakdown - The waxed wafer was placed into a control ring and run with Kemox 0-800S for 10 minutes, then hand cleaned with CO-42. Semi polish - The ASFL polishing pad was added to the plate and the waxed wafer was added into a plastic faced control ring and run with Kemet liquid diamond 3 micron type K for 10 minutes . CMP Process - The Chem-H pad was added to the plate and the waxed wafer was added into a plastic faced control ring. A second weight was added on top and run with a steady disperse of Col-K (NC) for 40 minutes.

Ra achieved : 0.0080µm. This process can only polish one side of the wafer due to the waxing method.

Before Surface Finishing Titanium

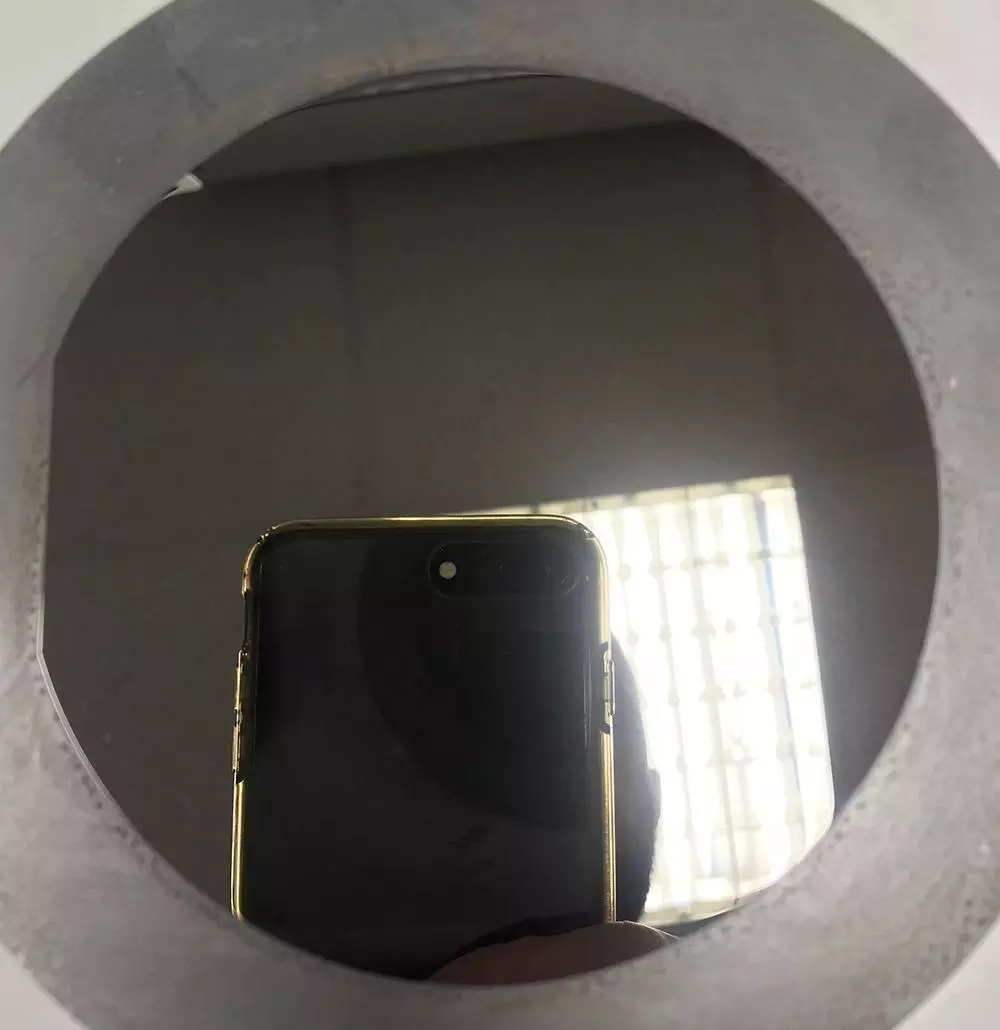

After Surface Finishing Titanium

Scope of Work: To mirror polish titanium components with a process that causes as little roll off as possible

Stage 1

- Machine Type: Kemet 15” diamond lapping/polishing machine

- Lap Plate: Kemet PR3

- Abrasive Type/Grade: Kemet Liquid diamond 6 micron type k standard

Stage 2

- Machine Type: Kemet 15” CMP polishing machine

- Lap Plate: Chem-H polishing cloth

- Abrasive Type/Grade: Col-k (N/C)

Process breakdown for Titanium

Using the PR3 plate gives you the best plate polish, whilst leaving the edges nice and sharp. The CMP process etches the surface for minimal roll off compared to a standard diamond silk polish. We achieved a surface finish Ra value of 0.018 µm. Parts ultrasonically cleaned using Kemet type A fluid.

Before Processing Titanium (Turned Part)

After Processing Titanium with 6 Micron PR3

After Processing Titanium with Col-K N/C CMP