Surface Finishing Injection Moulding

Surface finishing is a crucial aspect of injection moulding as it directly affects the final product's appearance, functionality, and durability. Proper surface finishing can enhance the aesthetics, reduce friction, and increase the lifespan of the product, while inadequate surface finishing can cause defects, reduce performance, and create safety hazards.

Why is Surface Finishing Important in Injection Moulding?

The surface finish of injection-moulded parts can have a significant impact on their performance and appearance. Smooth and uniform surfaces not only look good but also reduce friction, resist wear, and prevent dirt and debris buildup. On the other hand, rough or uneven surfaces can cause problems such as: Poor aesthetics: Surface defects like weld lines, sink marks, and ejector pin marks can ruin the visual appeal of the product, making it look cheap or unfinished. Reduced functionality: Rough surfaces can create drag, friction, and noise, leading to reduced functionality or even failure of the product. Increased wear: Parts with rough or uneven surfaces are more prone to wear and tear, which can shorten their lifespan and increase maintenance costs. Safety hazards: Sharp edges, burrs, or other surface irregularities can pose safety hazards, especially in products that come in contact with the skin or have moving parts. Therefore, achieving the right surface finish is critical to the success of any injection moulding project. To achieve a high-quality surface finish in injection moulding, various post-processing techniques can be employed. These techniques include sanding, polishing, and chemical etching, but one of the most effective methods is lapping and polishing.

Why Lapping and Polishing are the Best Choices for Surface Finishing Injection Moulding

Lapping and polishing are processes used to achieve a flat and smooth surface finish by removing a very thin layer of material from the surface. In injection moulding, lapping and polishing are typically done using a combination of abrasive pads and diamond compounds. The process involves moving the part back and forth over the abrasive pad in a circular motion, gradually reducing the roughness and improving the surface finish. One of the key advantages of lapping and polishing is that it can be used to achieve extremely high levels of surface flatness and smoothness. The process can remove imperfections as small as 1 nm, resulting in a surface that is almost mirror-like. This level of surface finish is critical for many applications where precision and accuracy are paramount, such as optical components, electronic parts, and medical devices. Another advantage of lapping and polishing is that it can be used to improve the mechanical properties of the part. The process can remove surface defects such as burrs and nicks, reducing stress concentration and improving the part's fatigue life. Additionally, the process can increase the surface hardness and wear resistance of the part, making it more durable and long-lasting.

Scope of Work: Lap and Mirror Polish 2 x Moulds

Stage 1 - Lapping: The first stage involved lapping the moulds using a 24” Kemet copper SP2 lapping plate. The plate was flat, and the moulds were placed centrally into a control ring. A 10 micron type K diamond slurry was dispensed at a ratio of 2 seconds of spray every 40 seconds. The moulds were run for 20 minutes and subjected to a Dycem faced pressure weight of 8kg. After the lapping process, the moulds were cleaned using CO42 cleaning fluid to check if grinding marks had been removed.

Stage 2 - Polishing: The second stage involved polishing the moulds using a 24” ASFL polishing cloth in the middle of a plastic faced control ring. A 3 micron type K slurry was dispensed at a ratio of 2 seconds of spray every 40 seconds. The moulds were run for 15 minutes and subjected to a Dycem faced pressure weight of 8kg. After the polishing process, the moulds were cleaned using CO42 cleaning fluid and inspected.

Lapping and mirror polishing are important processes in mould maintenance. The process involves the use of specialized equipment and materials such as lapping machines, polishing cloths, and diamond slurries. In this case, the moulds were subjected to a 20-minute lapping process followed by a 15-minute polishing process. The moulds were inspected after the polishing process to ensure that they were free from defects. This process will help to ensure that the moulds function efficiently and produce quality products.

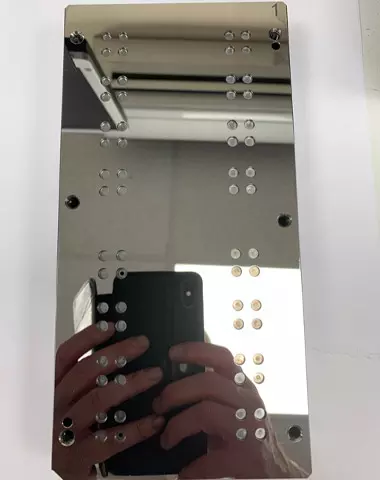

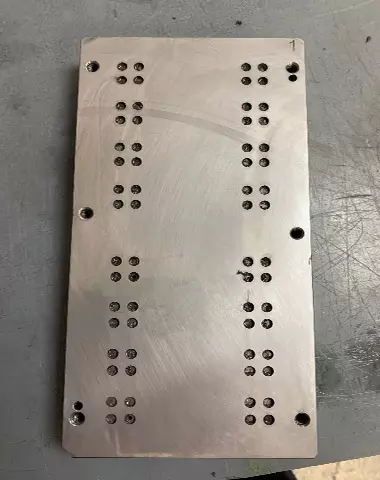

Before Surface Finishing Injection Moulding

After stage 1 Processing Injection Moulding

After Surface Finishing Injection Moulding