Surface Finishing Cobalt Chrome

Cobalt chrome is an alloy (Co-Cr) that is ideally used for orthopaedic implants. There is a high demand for dimensional accuracy that can be achieved precisely by using Lapping and Polishing processes. Kemet has worked with some of the largest manufacturers for many years, in which they need to finish cobalt chrome parts to the highest flatness and surface finish specifications.

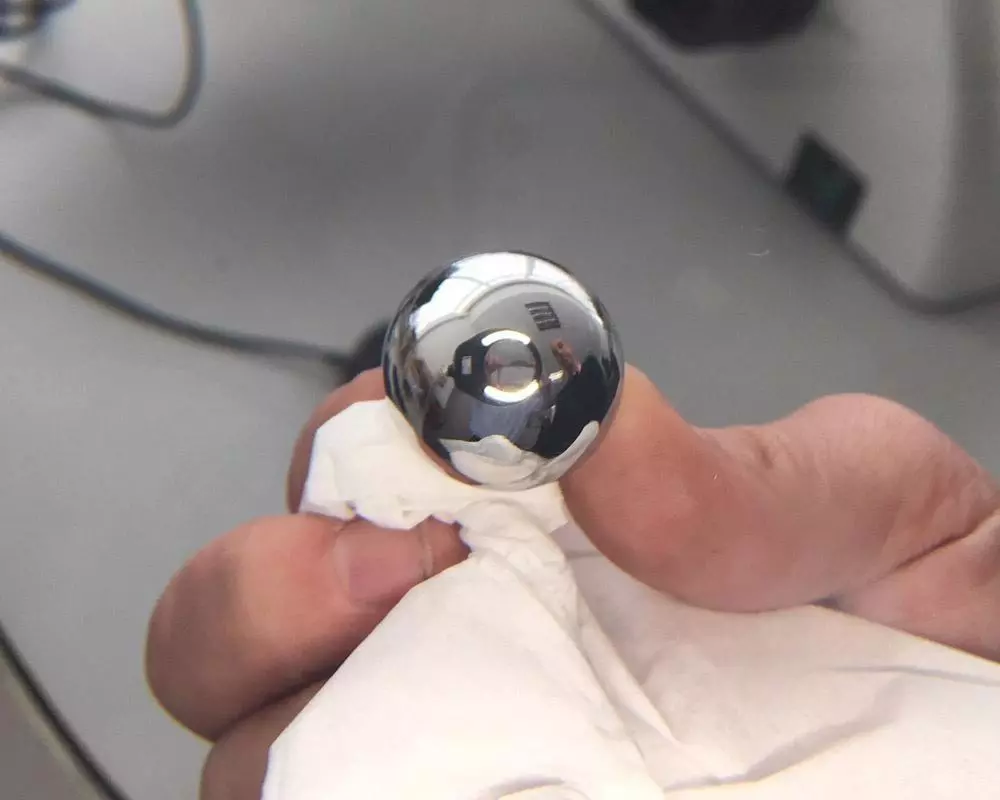

Scope of Work: To mirror polish 5 x 32mm cobalt chrome balls

Equipment used:

- Kemet Spherical polisher

- Cast iron lap

- NLH cloth

- Kemet Diamond compound 14-KD-C2 and 1-KC547

- OS lubricating fluid

- CO-42 cleaning fluid

- Precise tooling

Process

NLH cloth & 14-KD-C2 and 2 sprays of OS lubricating fluid at 30 psi pressure. Run time = 10 minutes. NLH cloth & 1-KC547 diamond compound and 2 sprays for OS lubricating fluid at 30 psi pressure. Run time = 10 minutes. Total run time per part = 20 minutes.

Results

The surface finish was measured at the top of the ball and achieved a Ra of 0.0084 µm. No scratches were visible under x5 microscope. A 2 stage process was required to reduce the polishing time to under 25 minutes. Lapping with silicon carbide was not required.

After Surface Finishing Cobalt Chrome

Scope of Work: To mirror polish 12 x cobalt chrome cups, 50mm diameter

Equipment used:

- Kemet Spherical polisher

- Cast iron lap

- NLH cloth

- Kemet Diamond compound 1-KC547

- OS lubricating fluid

- CO-42 cleaning fluid

- Precise tooling

Process for surface finishing cobalt chrome cups

The lap was fitted to the drive boss of the spherical polisher, a square of NLH cloth was placed on top with 1-KC547 diamond compound applied to the middle, the machined ball was pushed onto the machined shaft and inserted into the yoke holder and placed onto the cloth, a slight spray of OS lubricating fluid was then applied and was run for between 15-20 minutes till polished up. Note: The angle of the sweep for polishing the cups were changed compared with the angle of sweep for polishing the heads.

Surface finish results

Surface finish: 0.0122 µm. Roundness was 4.33 µm

After Surface Finishing Cobalt Chrome

Scope of Work: To mirror polish 2 x W604 cobalt chrome cups in under 25 minutes each

Equipment used:

- Kemet Spherical polisher

- Cast iron lap

- MRE cloth

- Kemet Diamond compound 1-KC547

- OS lubricating fluid

- CO-42 cleaning fluid

- Precise tooling

Process

MRE cloth & 1-KC547 diamond compound and 2 sprays for OS lubricating fluid at 40 psi pressure. Run time = 20 minutes.

Results

To reduce scratching around the rim, 3 felts were put on top of the lap. No pips were visible in the cup and no scratches were visible at the rim. Lapping with silicon carbide was not required.

After Surface Finishing Cobalt Chrome