Superfinishing with Kemet’s PR3 Composite

Superfinishing is a machining process that produces an ultra-smooth surface finish on a workpiece, which is essential for various industrial applications. However, achieving a surface finish of less than 0.01µm Ra presents a number of challenges that often require trade-offs to achieve the desired results. One of the most common methods for superfinishing involves a two-step process, starting with a lapping operation to produce a flat and uniform surface finish, followed by a polishing operation that uses a polishing pad to generate the superfinish. This approach works for many parts, but it has a drawback called "roll-off," which is the removal of any sharp edges during the polishing process. Roll-off can be a problem in some applications, especially those that require sealing components, where the sharp edges are critical to maintaining the component's integrity.

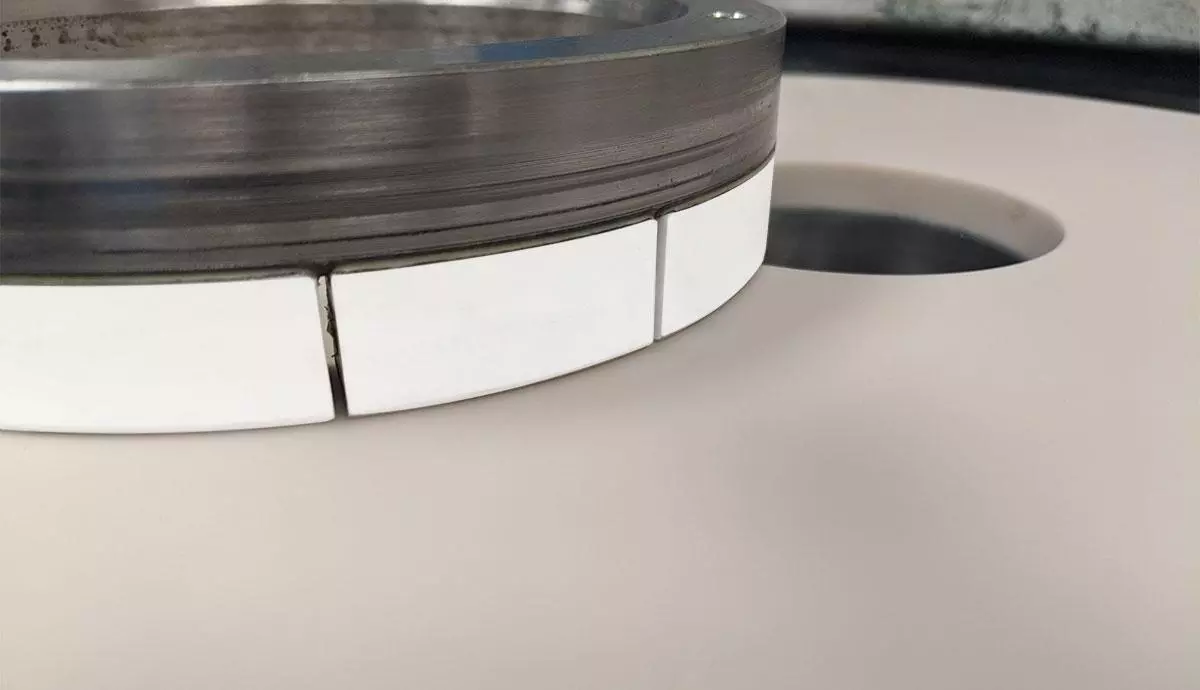

To address this issue, Kemet has developed a new composite plate material called PR3, which, in combination with its closely graded diamond slurries and compounds, can produce a surface finish value better than what would be expected from a purely polishing process while still having the ability to remove material. Furthermore, the PR3 has no metal content within the composite, making it ideal for applications where components must not be in contact with metals, such as in nuclear and electronics.

The lack of metal in the PR3 plate, combined with the use of ceramic faced conditioning rings, ensures that parts are much cleaner after lapping, especially when using white aluminium oxide based ceramic materials. Additionally, since the surface finish after the PR3 is so good on many materials, there is often no need to follow it with a pad polishing stage. However, in cases where secondary pad polishing is needed, the polishing time is short enough for no roll-off to be produced.

For component designers who need to maintain sharp edges, the Kemet PR3 composite plate material offers an ideal solution for producing a superfinish without compromising the integrity of the component. Furthermore, Kemet offers free testing for any lapping or polishing applications, regardless of whether an existing process is in place.