Safety Valve Maintenance or Repair using Lapping

When it comes to ensuring the reliability and efficiency of safety valves, proper maintenance and repair are crucial. Safety valves play a vital role in various industries by preventing excessive pressure build-up in systems and equipment. To optimise their functionality, it is essential to address any potential issues promptly. That's where Kemet Diamond Lapping machines come into play, providing an ideal solution for lapping and repairing safety valves with ease and precision.

At Kemet, we understand the importance of maintaining safety valves in peak condition. Our lapping machines are designed to streamline the maintenance and repair process, ensuring the safety valve seat is lapped quickly, reproducibly, and effectively. With our advanced diamond technology, safety valve maintenance has never been easier.

One of the significant advantages of using Kemet Diamond Lapping machines is the ability to lap safety valve seats in under five minutes. This remarkable efficiency allows for swift turnaround times, minimising equipment downtime and maximising productivity. By significantly reducing the time required for maintenance, our machines help businesses save valuable resources and maintain optimal operational efficiency. Moreover, our diamond lapping technology ensures the production of flat parts during the maintenance process. This flatness is crucial in achieving a perfect seal, eliminating the possibility of leakage. By creating a precise and uniform contact surface between the safety valve seat and the valve body, our machines contribute to the longevity and effectiveness of safety valves. Another noteworthy feature of Kemet Diamond Lapping machines is their versatility. Our process can be applied to a wide range of materials, including bronze, stainless steel, and more. Regardless of the material used in the safety valve, our machines provide consistent and reliable results. This adaptability allows businesses across various industries to benefit from our technology, regardless of the specific materials they employ.

Safety valve maintenance is a critical aspect of ensuring the safety and reliability of industrial systems. Neglecting proper maintenance can lead to costly consequences, including equipment failure, production delays, and even potential safety hazards. By incorporating Kemet Diamond Lapping machines into their maintenance protocols, businesses can proactively address safety valve issues and prevent such complications. In addition to the numerous advantages already mentioned, Kemet Diamond Lapping machines offer a user-friendly interface, making them accessible to operators of all skill levels. Our machines are designed with simplicity and efficiency in mind, enabling operators to achieve optimal results without extensive training or technical expertise. This accessibility further enhances the practicality and effectiveness of our machines in diverse industrial settings.

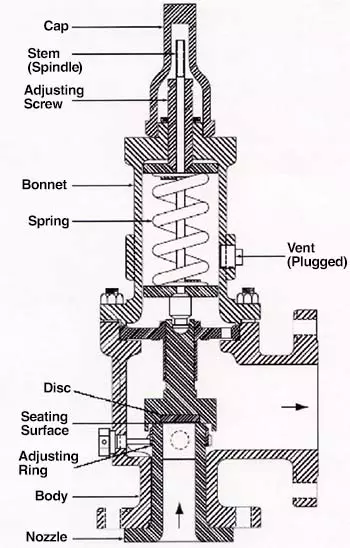

Using Kemet Lapping Machines, you can lap the Disc and the Seating Surface

To begin, start by disassembling the Safety Valve carefully, ensuring all necessary safety precautions are taken. Once disassembled, you can focus on the Disc and the Seating Surface for lapping. For the Disc, it is recommended to remove it from the assembly and proceed with the lapping process using a Kemet diamond lapping machine. Ensure that the machine is equipped with a Kemet XP plate and utilize Kemet liquid diamond with a 6 Micron standard concentration. This combination will facilitate efficient material removal and provide a smooth, polished surface for the Disc.

Moving on to the Seating Surface, first check if it can be removed from the assembly. If it is removable, take it out and place it on the Kemet diamond lapping machine, again using the Kemet XP plate and Kemet liquid diamond with a 6 Micron standard concentration. This setup will enable you to achieve optimal lapping results, improving the seating surface's flatness and overall quality. However, if the Seating Surface cannot be removed from the assembly, there is an alternative approach. Utilize a Kemet valve lapping kit designed specifically for this purpose. This kit will allow you to lap the seating surface in situ, without the need for disassembly. Follow the instructions provided with the kit to effectively and safely lap the seating surface, ensuring a proper fit and sealing performance.