Lapping & Polishing Steel - Case Study

Test Requirements:To recommend the shortest process needed to lap and polish a steel sample.

Component/Material: 1 x steel sample.

Process for polishing Steel components

The Kemet Iron lapping stage is a fast method to produce a flat and evenly graded surface; and by following this with an ASFL-AW silk polishing stage, no other lapping plate is needed. The cloths are simply fixed using a self adhesive backing to the Kemet Iron plate once parts are ready for polishing.

Results: After polishing our sample showed an Ra 0.003

| Process Breakdown | |||

|---|---|---|---|

| Stage | Plate/cloth type | Abrasive type/grade | Process time |

| 1 Lap | Kemet Iron | Type K Standard Diamond slurry | 15 minutes |

| 2 Polish | ASFL-AW silk polishing pad | Type K Standard Diamond slurry | 10 minutes |

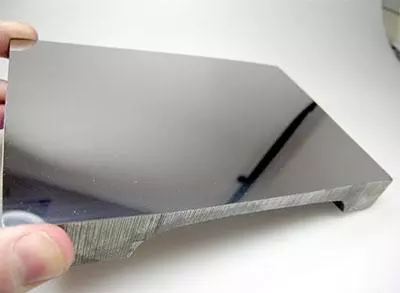

Before Lapping Steel

After Lapping Steel

After Polishing Steel

Test Requirements: To produce a mirror polish on Steel components.

Component/Material: 6 off 80mm x 115mm Steel Plates.

Process for producing mirror finish to Steel

We used a combination of conventional lapping for stage 1, followed by diamond polishing for stage 2. Both processes could be performed on a single Kemet 24 Diamond Lapping machine.

| Process Breakdown | |||

|---|---|---|---|

| Stage | Plate/cloth type | Abrasive type/grade | Process time |

| 1 Lap | Cast Iron | Kemox O-800S | 15 minutes |

| 2 Polish | ASFL polishing pad | Type K Standard Diamond slurry | 12 minutes |

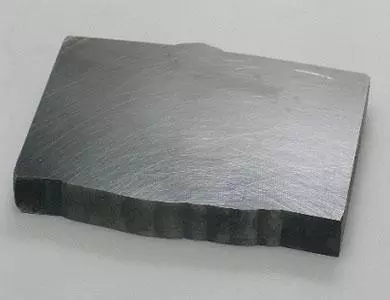

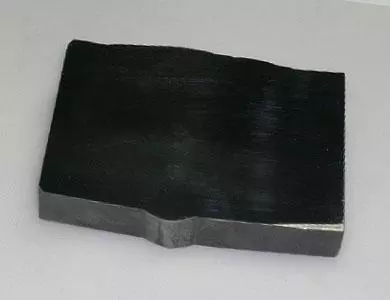

Steel plate before lapping

Steel plate after lapping

Steel plate after Polishing

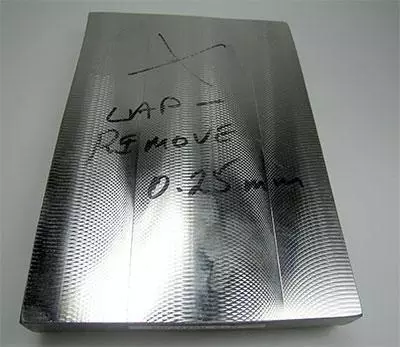

Test Requirements: To remove 0.25mm from steel rail part and then mirror polish

Component/Material: 6 off 80mm x 115mm Steel Plates.

Comments: It took 90 mins to remove 0.25mm material

| Process Breakdown | |||

|---|---|---|---|

| Stage | Plate/cloth type | Abrasive type/grade | Process time |

| 1 Lap | Kemet Iron | Type K Standard Diamond slurry | 90 minutes |

| 2 Polish | ASFL polishing pad | Type K Standard Diamond slurry | 20 minutes |

Before lapping Steel part

After lapping Steel part