Lapping & Polishing HSS Steel

High-Speed Steel (HSS) is widely used in industrial applications due to its superior hardness, wear resistance, and ability to retain sharp edges at high temperatures. Achieving a mirror finish on HSS surfaces is critical for improving performance in high-precision applications. The process involved two distinct stages: lapping and mirror polishing, using specialised equipment and materials.

Process Breakdown

The HSS samples were processed in two sequential stages to achieve a mirror finish:

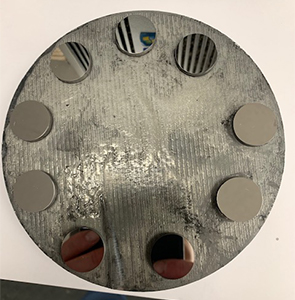

Stage 1: Lapping Process - The setup involved evenly positioning ten HSS samples on a Kemtak Plus Faced 15” Pressure Weight. These samples were then placed within a 15” Control Ring on a flat Kemet Iron Lapping Plate. The plate was driven by a Kemet 15” Diamond Lapping/Polishing Machine to ensure consistent material removal and surface uniformity. During operation, the machine was run for 20 minutes, applying Kemet Liquid Diamond 14 Micron Type K Slurry at a controlled rate of 2 seconds of spray every 40 seconds. Once the lapping process was complete, the samples were thoroughly cleaned using Co42 Cleaning Fluid to remove residual abrasive and contaminants.

Stage 2: Mirror Polishing Process - The lapped samples were transferred to a Kemtak Plus Faced 15” Pressure Weight and placed inside a Plastic Faced Control Ring on an ASFL Polishing Cloth. This setup was then mounted on a Kemet 15” Lapping/Polishing Machine to ensure precise polishing. The polishing process was conducted for 10 minutes, during which Kemet Liquid Diamond 3 Micron Type K Slurry was applied at a rate of 2 seconds of spray every 40 seconds. Once the polishing cycle was complete, the samples were carefully removed and thoroughly cleaned using Co42 Cleaning Fluid to eliminate any remaining slurry or contaminants.

Surface Finish Achieved - The final surface roughness (Ra) achieved after the mirror polishing process was 0.0088µm, indicating a highly refined surface suitable for high-precision applications.

Equipment and Materials Used

- Kemet 15” Lapping Machine

- Kemet Iron Plate (15” diameter)

- ASFL Polishing Cloth

- Kemet Flatness Gauge

- Plastic Faced Control Ring

- Kemtak Plus Faced Pressure Weight

- 14 Micron Type K Standard Diamond Slurry

- 3 Micron Type K Standard Diamond Slurry

- Co42 Cleaning Fluid

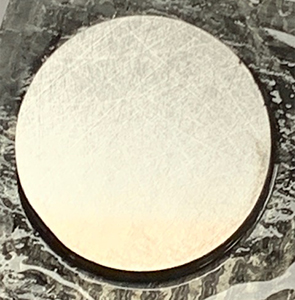

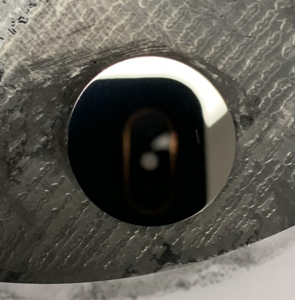

Before Processing

After Lapping

After Polishing

Workholder example

What is HSS steel used for?

High-Speed Steel (HSS) is used primarily in applications that require high wear resistance, hardness, and the ability to retain sharp edges at elevated temperatures. Some common uses include:

- Cutting Tools – HSS is widely used for manufacturing drill bits, milling cutters, saw blades, taps, reamers, and lathe tools due to its excellent edge retention and durability.

- Industrial Machinery Components – Gears, punches, and dies made from HSS benefit from its toughness and heat resistance.

- Cold Work Tooling – HSS is used in applications such as stamping and forming tools that require high resistance to abrasive wear.

- Aerospace and Automotive Industries – Precision components, especially those exposed to high temperatures and mechanical stress, often utilise HSS.

- Medical Instruments – Surgical tools and precision instruments are sometimes made from HSS due to its strength and resistance to corrosion.