Lapping & Polishing Clipper Blades (Sharpening)

Lapping is an essential process in maintaining high-performance clipper blades. By using precision equipment and controlled parameters, the lapping process enhances the sharpness, longevity, and efficiency of the blades. Whether used in pet grooming, hairdressing, or industrial applications, properly lapped clipper blades provide superior performance, making them an invaluable tool for professionals.

The primary objective of lapping clipper blades is to achieve a perfectly flat and smooth surface, ensuring efficient and consistent cutting performance. This process enhances the sharpness and longevity of the blades while minimising friction and wear.

Process Breakdown

The lapping process was carried out in a structured manner to ensure uniformity and precision. Each clipper blade was centrally positioned into a 15” control ring to maintain alignment. A felt pad was placed on top of the blade to compensate for any uneven top profile, ensuring uniform pressure distribution. To maintain consistent pressure on the blade during lapping, a Dycem faced pressure weight was applied.

The Kemet Iron lapping plate was cycled with Kemet liquid diamond (14-micron Type K Std) dispensed at a controlled ratio of 2 seconds of diamond spray every 45 seconds until the blade surface achieved the desired finish. The processing time varied depending on the component size. For larger blade components, the media used was 14 Micron Type K Std, with a Kemet Iron plate and a weight of 4kg, running for 3 minutes per side. Smaller blade components underwent the same process but were lapped for 2 minutes per side.

Finally, processed clipper blades were cleaned using CO42 cleaning fluid to remove all residual abrasive material and ensure a polished finish. The process times can be optimised by increasing the micron size of the liquid diamond or applying additional weight. This can expedite material removal while maintaining precision.

The following clipper blades underwent lapping: Oster: Number 4, Size 10, Size 3F, Elite Size 3½, Andis: Number .000, Number .5, 16mm, Artero: 19mm, Size 5/8

Equipment and Materials Used

- Kemet 15” Lapping Machine

- Kemet Iron Plate (15” diameter)

- Kemet Flatness Gauge

- Dycem Faced Pressure Weight

- Liquid Diamond 14 Micron Type K Std

- Co42 Cleaning Fluid

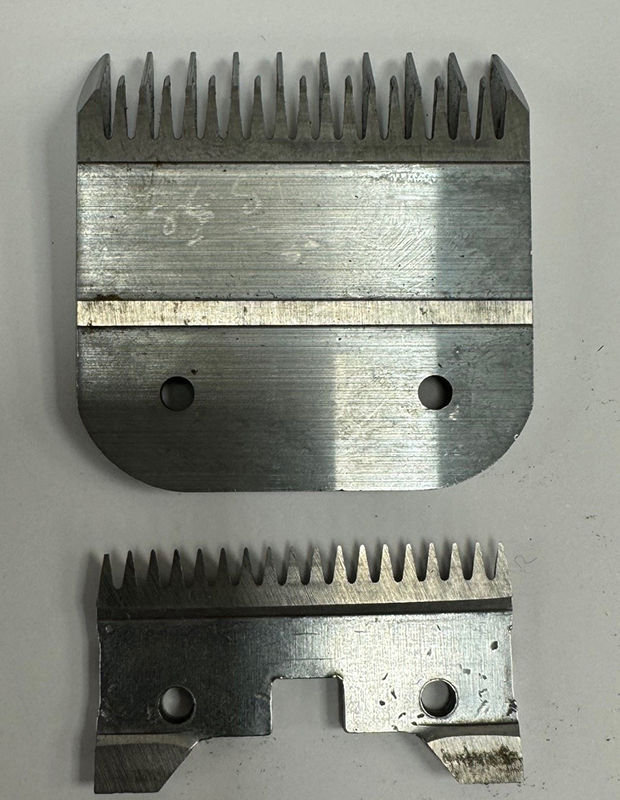

Before Processing

Before Processing

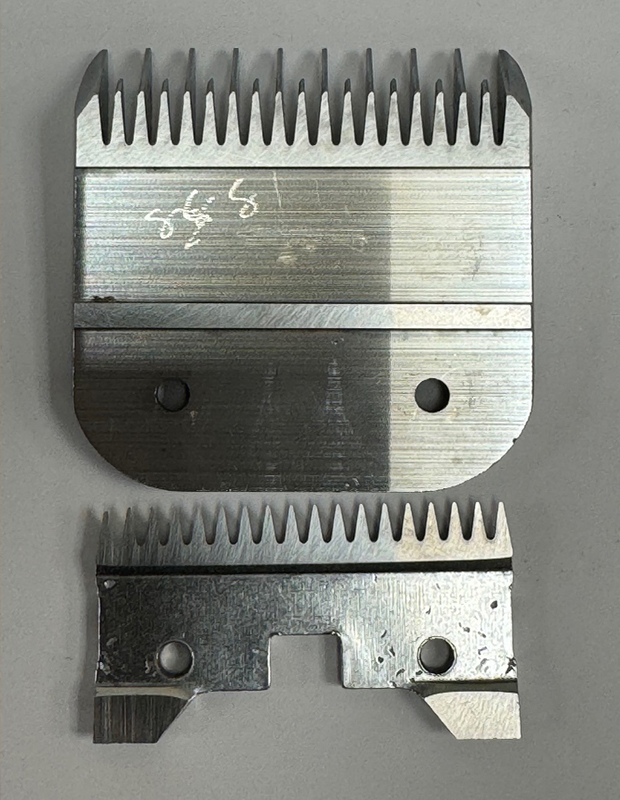

After Lapping

Flatness reading 0.00029mm

Benefits of Lapping Clipper Blades

Lapping clipper blades offers numerous advantages. One key benefit is improved sharpness and cutting efficiency. The process ensures a razor-sharp edge, enhancing the blade's cutting precision and reducing the need for frequent sharpening. Another advantage is the extended lifespan of the blade. By reducing wear and tear and providing a smooth and even surface, lapping helps prolong the blade's durability. Consistent flatness and uniformity are also ensured, allowing even contact between the moving and stationary blades. This prevents uneven cutting and enhances performance. Additionally, lapping reduces heat and friction. A smoother blade surface generates less heat and friction, minimising discomfort for the user and the subject being groomed. This contributes to a better overall experience. The process also minimises maintenance requirements. A well-lapped blade maintains sharpness longer, reducing the need for frequent sharpening and replacement. Finally, enhanced user experience is a significant benefit. Professional groomers and barbers benefit from improved blade reliability, leading to more precise and effortless grooming sessions.