Lapping plate flatness - Maintenance procedures

It is recommended that when in continual use, Lapping Plates should be inspected for flatness at least twice a day. The best and fastest method for checking plate flatness is the use of a Flatness Gauge. This consists of a dial indicator (calibrated to 0.001mm) supported on three points and set to zero on a known flat test piece. The gauge can be used to take readings over several areas of the Lapping Plate. The average of the readings obtained can then be used in conjunction with a graph on the back of the gauge to predict the resulting flatness of parts in light bands that the plate in its current condition will produce.

Generally a lapping plate will wear evenly convex or concave over time. The Flatness gauge is telling the user the flatness of the lapping plate over the span of the gauge (236mm). If the plate is wearing evenly, the gauge reading should be the same wherever it is positioned on the lapping plate. For lapping plates over 380mm ø the gauge reading is not the total flatness of the plate. However, the gauge reading will predict resulting flatness of parts from any size of lapping plate, and will also show whether a plate is convex or concave. The Flatness Gauge can also be used to set a plate flatness tolerance where an operator will know that if the reading is outside the validated tolerance, plate correction is required.

If the readings from a Flatness Gauge are not the same across a lapping plate, it can be necessary to use a Straight Edge and Feeler Gauges to determine exactly what shape a lapping plate has become. If this is the case, it can point to excessive pressures on the parts being lapped, or other set up issues.

Bringing Plates to Flatness

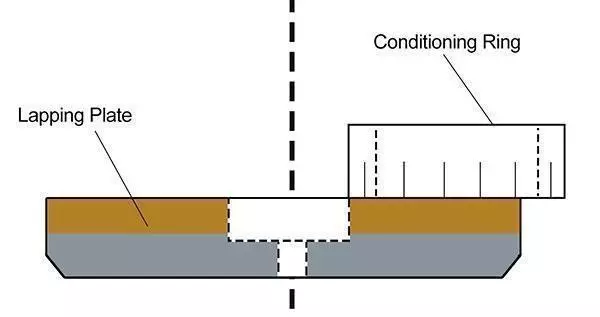

Small variations in flatness can often be corrected by moving the conditioning rings ‘in’ to correct a convex plate or ‘out’ to correct a concave plate. However, plates should not be allowed to become too convex as correcting this condition can be Time consuming. The method of conditioning and flattening plates is as follows:

Correcting concave lapping plates

- Move all conditioning rings outward and start the machine whilst applying the Kemox HSR abrasive slurry. This should be between the conditioning rings as their rotation will draw the Abrasive to the outer area of the Kemet Plate.

- Check Plate flatness at regular 5 minute intervals, until the correction rate has been established. This is important as the flatness correction from concave can be several time faster than from convex and it is possible to go past the flat condition to the convex.

How to Correct a Concave Cast Iron lapping Plate

- Position the conditioning ring to overhang the lapping plate

- If all 3 conditioning rings can be used, then it is better

- Start the lapping machine and add Kemox HSR abrasive slurry

- When the plate is flat clean the surface with either CO42 or Dasty to remove all traces of the aluminium oxide. Clean the conditioning rings, and the re-charge the lapping plate with diamond slurry before starting production.

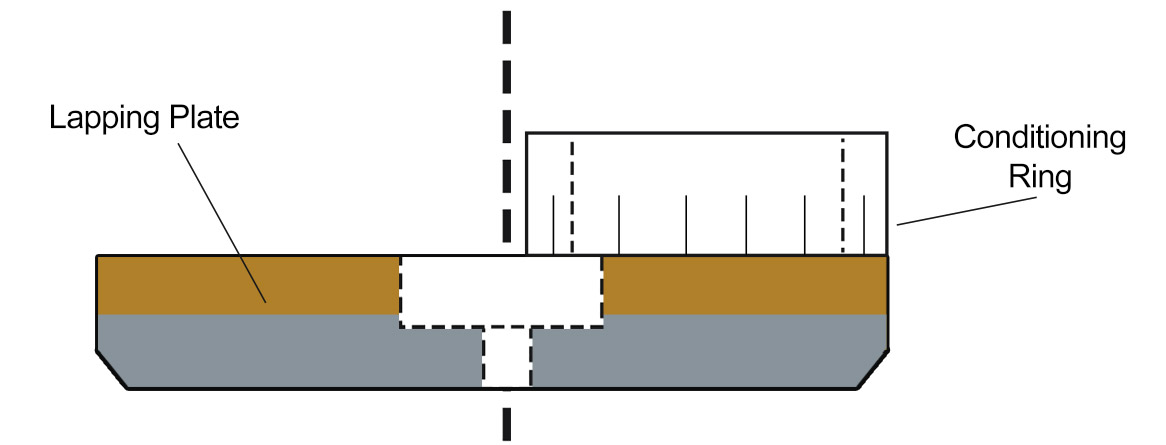

Correcting a convex lapping plate

- Remove one of the machines conditioning rings.

- Position the ring or rings towards the centre of the plate, ensuring that a ring just sweeps over the outer edge to prevent a step being formed by the conditioning process.

- Fill the abrasive system of the machine with the correct slurry based on stock removal needed, Kemox HSR has the highest stock removal at 29um, Kemox 400 is 23um and Kemox 800 is 14um.

- Start the machine and allow the mixture to drip on to the Kemet Plate.

- This method should correct a 15 or 24” diameter Kemet Lapping Plate at the rate of 0.005-0.01mm each 20 minutes. From this it can be seen that if a plate is extremely convex, consideration should be given to having it turned or re-machined.

Cleaning a lapping plate after conditioning

After conditioning all Kemet Plates should be cleaned using a solvent such as Kemet CO-42 or Dasty, until there are no traces of the Abrasive. This also applies to the conditioning rings which should if possible be cleaned ultrasonically.

Changing grades of Kemet liquid diamond

It is possible to change grades of Liquid Diamond by simply changing the containers on the machine, however, if the change is to a finer micron size of Diamond than previously used, it is necessary to recondition the Kemet Plate using the above process to remove any Abrasive/Contamination. After cleaning the plate can then be charged with the finer grade.

When to replace a Lapping plate

When thickness is less than 3mm, replace plate.

After extended use Kemet Plates will become worn. A re-facing service is offered and a quotation will be supplied on request.