Lapping Hard Materials

Lapping is a precision machining process that involves the use of an abrasive material and a lapping plate to remove small amounts of material from a workpiece. This process is particularly useful for hard materials such as ceramics, glass, and metals, which are difficult to machine using conventional methods. Lapping is the best option for lapping hard materials due to its ability to produce a superior surface finish, achieve tight tolerances, reduce stress, offer flexibility, and be cost-effective. By choosing lapping as a machining method, manufacturers can produce high-quality parts that meet the demands of their customers and the industry.

Achieving a Surface Finish of Ra Below 0.2 µm and Flatness Better than 0.0006mm in 15 Minutes on Ceramic Parts

The high-accuracy surface finishing for ceramic parts holds immense significance across several industries. The method of lapping and polishing discussed below, utilising the Kemet 36” lapping/polishing machine and associated equipment, delivered exceptional outcomes, yielding a surface finish of 0.0971µm and flatness of 0.00029mm within a span of 15 minutes. This process exhibits versatility and can be employed for a diverse range of ceramic parts to comply with the rigorous dimensional and surface quality standards of numerous industries.

Process breakdown: The following steps were taken to lap and polish the ceramic parts: 73 ceramic parts were placed in a profiled workholder. A Dycem backed 36” pressure weight was placed on top of the components to provide even pressure during lapping and polishing. The workholder with the ceramic parts and pressure weight was placed on the Copper SP2 lapping plate of the Kemet 36” lapping/polishing machine. The machine was turned on and the ceramic parts were run on the lapping plate for a total of 15 minutes using Kemox 0-400 as the lapping compound. After 15 minutes, the ceramic parts were removed from the lapping plate and ultrasonically cleaned with Kemet type A cleaning fluid. The ceramic parts were then polished with Kemet Liquid Diamond 6 Micron Type K Std for 5 minutes. The ceramic parts were again ultrasonically cleaned with Kemet type A cleaning fluid. Finally, the ceramic parts were inspected using a Kemet flatness gauge to measure their flatness.

Results: After the above process, the ceramic parts achieved a surface finish of 0.0971µm and flatness of 0.00029mm, which met the desired specifications of Ra below 0.2 µm and flatness better than 0.0006mm. The process was completed in under 15 minutes, making it a highly efficient process for lapping and polishing ceramic parts.

Equipment used:

- Kemet 36” lapping/polishing machine

- 36” diameter Copper SP2 Lapping plate

- Kemet Flatness gauge

- Kemox 0-400

- Kemet Liquid diamond 6 micron type K std

- Dycem faced pressure weight

- CO-42 cleaning fluid

- Profiled workholder

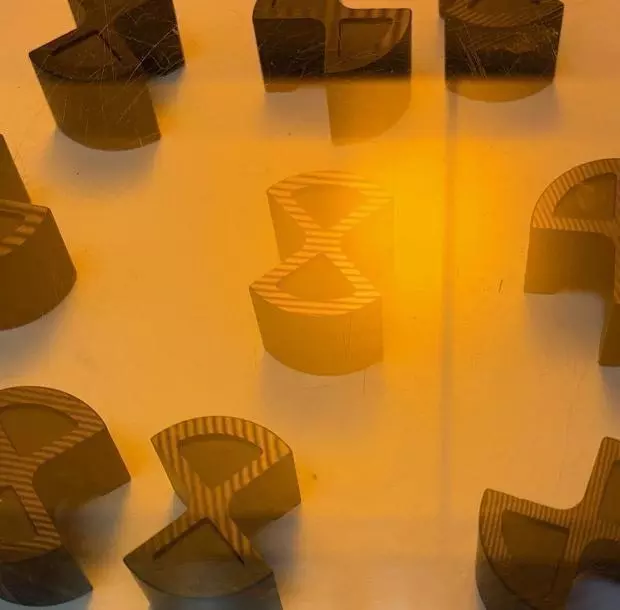

Profiled

workholder

Before Surface

Finishing Ceramic

After Surface

Finishing Ceramic

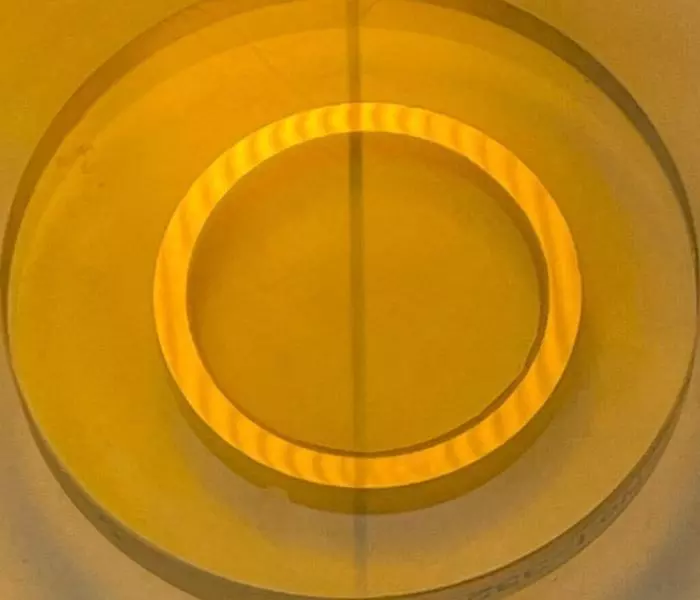

Flatness Reading of Ceramic to better than 1 light band

Reworking and Lapping 4 Tungsten Carbide Seal Faces

The equipment used for this task includes a Kemet 15” lapping/polishing machine, Kemet Copper SP2 lapping plate, Kemet Flatness gauge, 6 micron type k std, CO-42 cleaning fluid, and Dycem faced pressure weight.

Process Breakdown for Tungsten Carbide Seals: To rework and lap flat the Tungsten Carbide Seal Faces, the seal faces were placed centrally inside a 15” control ring on a Kemet copper SP2 lapping plate. A dycem faced hand weight was placed on top of the faces to act as a fixture to protect the parts. Then, the machine was operated by dispensing 6 micron type k at a ratio of 2 seconds of diamond spray every 45 seconds until each face had been cleaned up. This process was repeated for all faces. Finally, the seal faces were taken off and cleaned with CO42 cleaning fluid to remove any residue or contaminants.

Before Processing Tungsten Carbide Seals

After Processing Tungsten Carbide Seals