Improve Your Lapping Machine With New Modifications - Cut Your Lapping Costs

Bring your Lapping Machine back to its full potential and save money in the long run through improved productivity. What can Kemet International do to improve your current setup;

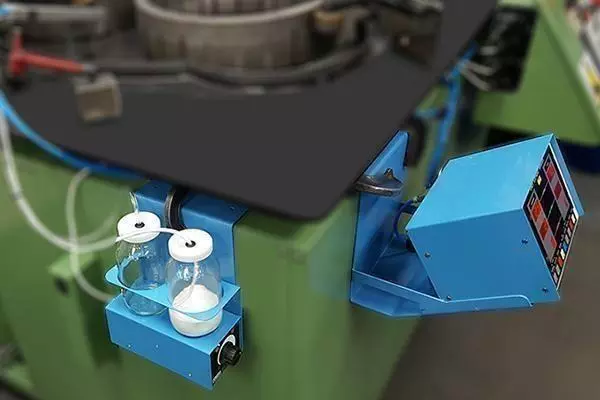

- Installation of new dispensing system

- Full service of the machine

- Consultation with our technical team for improvements to your current process

- Installation of composite plate

- Training to improve staff productivity

Why Diamond Lapping Works

The hard Diamond particles become embedded in the composite lapping plate, this gives support to the Diamond enabling it to cut more efficiently.

- Hard materials are cut very effectively.

- Because the surface is cut cleanly, it offers better light reflective qualities.

- Better visual surface finish.

- Optical Flat inspection without separate polishing operation.

The Benefits Of Diamond Lapping Compared With Conventional Lapping

This video explains the benefits of diamond lapping compared with conventional (silicon carbide / aluminium oxide) lapping. The main advantage is that diamond lapping produces a polished surface in 1 step, with a faster polishing time, faster material removal and less waste

Samples are evaluated free-of-charge & reports are issued covering all aspects of the process & the likely consumable costs involved.

We provide a complete technical support programme as part of our package. Our team of technical experts are always on hand to offer advice and assistance.

With over 85 years of expertise, our experienced in-house technical support team can help you with your processes.