Ultrasonic Cleaning Palladium, SmCo20s magnet, Ryton BR111 - Case Study

In the manufacturing of small electrical components, maintaining high standards of cleanliness is crucial. Contaminants such as machining oils, over-moulding release agents, and loose flashing can severely impact the performance and reliability of these components. Materials commonly used in these components include Stainless 316, Brass, Copper, Palladium, Silver, SmCo20s magnet, and Ryton BR111. Ultrasonic cleaning presents an effective solution to ensure these materials are impeccably clean. Ultrasonic cleaning uses high-frequency sound waves to create cavitation bubbles in a cleaning solution. These bubbles implode upon contact with surfaces, dislodging contaminants without damaging the material. This method is highly effective for complex geometries and delicate materials, making it ideal for small electrical components.

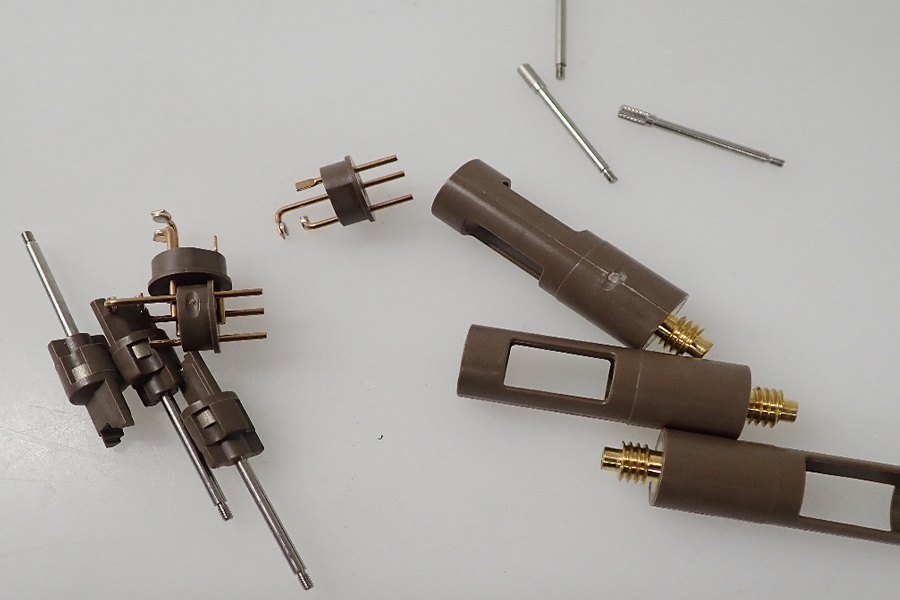

Component: Small electrical components

Material: Stainless 316, Brass, Copper, Palladium, Silver, SmCo20s magnet, Ryton BR111

Contamination prior to cleaning: Machining oils at the component stage, over-moulding release and loose flashing at the sub-level

Stage 1: Galvex 20.02, a universal detergent, is chosen for its compatibility with a wide range of materials and its ability to leave parts with a spot-free finish. The parts are loaded into a wash basket, the basket undergoes a 5-minute cleaning cycle in a 3% Galvex 20.02 solution heated to 40°C. Stage 2: After ultrasonic cleaning, parts are rinsed in tap water for 2 minutes. This static rinse helps remove any residual detergent without the need for ultrasonic cavitation. Stage 3: Finally, parts are dried in a recirculating hot air dryer for 10 minutes at 60°C, ensuring all moisture is eliminated.

| Ultrasonic Cleaner | Cleaning Agent | Temperature(s) | Concentration |

|---|---|---|---|

| 1. K-Sonic 30 benchtop ultrasonic cleaner | Galvex 20.02 | 40°C | 3% |

| 2. K-Sonic 30 benchtop ultrasonic cleaner | Tap water | 20°C | 100% |

| 3. Versa Genius+ 120 hot air dryer | N/A | 60°C | N/A |

Note: All stages were allowed to reach the required temperature and degas before cleaning.

Before cleaning

Parts in Basket

After cleaning

Palladium is widely used in electrical contacts and connectors due to its excellent conductivity and corrosion resistance. Ultrasonic cleaning effectively removes machining oils and contaminants from palladium surfaces without causing abrasion or corrosion, maintaining its conductive properties and prolonging component life.

Samarium-Cobalt (SmCo) magnets are critical in high-performance applications due to their superior magnetic properties and thermal stability. Ultrasonic cleaning ensures the removal of machining oils and loose flashing, which could otherwise interfere with the magnetic field. This method preserves the magnet's integrity and performance characteristics.

Ryton BR111, a high-performance thermoplastic, is used for its excellent chemical resistance and mechanical strength. During manufacturing, over-moulding release agents and loose flashing can compromise its performance. Ultrasonic cleaning with Galvex 20.02 efficiently removes these contaminants without degrading the material, ensuring optimal performance in its final application.