How Does Ultrasonic Cleaning Work

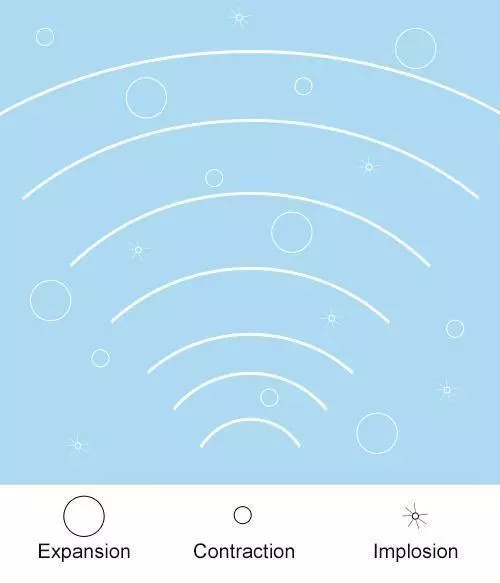

Ultrasonic cleaning is a highly effective method for removing dirt, debris, and other contaminants from various surfaces. This process relies on high-frequency sound waves that create tiny, high-pressure implosions in a liquid cleaning solution. When these bubbles collapse, they create intense local energy that dislodges and removes even stubborn contaminants. Ultrasonic cleaning equipment typically consists of a tank filled with a cleaning solution, an ultrasonic generator, and transducers. The transducers are usually mounted on the bottom or sides of the tank and are responsible for creating the sound waves that cause the cleaning action. The cleaning solution used in an ultrasonic cleaner is critical to the success of the process. The solution is typically a mixture of water and a specialised cleaning agent that is tailored to the specific cleaning task.

The ultrasonic cleaning process begins by placing the object to be cleaned into the tank filled with the cleaning solution. The object is then subjected to high-frequency sound waves generated by the ultrasonic generator and transducers. These sound waves create millions of tiny bubbles in the cleaning solution, which rapidly expand and then collapse. This process is called cavitation, and it creates intense local energy that dislodges and removes even the most stubborn contaminants from the surface of the object being cleaned. The cleaning solution in the tank is usually heated to enhance the cleaning action. Heat increases the rate of chemical reactions and makes it easier for the cleaning solution to penetrate and dissolve contaminants on the surface of the object.

Common Questions related to Ultrasonic Cleaning

Why do you need to Degas an Ultrasonic Cleaner

Degasging refers to the process of removing trapped air from the cleaning solution used in ultrasonic cleaning. When water is first introduced into the ultrasonic cleaner, it contains dissolved air, which can interfere with the cleaning process. Degasging the solution removes the trapped air, which allows the ultrasonic waves to penetrate deeper into the cleaning solution, providing a more thorough cleaning process.

Improved cleaning efficiency is a key benefit of degasging an ultrasonic cleaner. By allowing the sound waves to penetrate the cleaning solution more effectively, a more thorough cleaning process is achieved, resulting in cleaner and more polished surfaces. Degasging also ensures consistent cleaning results. The removal of trapped air ensures that the ultrasonic cleaning process is performed under the same conditions every time, providing reliable and repeatable results.

Degasging an ultrasonic cleaner also helps to extend the life of the equipment. Trapped air can cause bubbles to form in the cleaning solution, which can create cavitation erosion and damage the cleaning tank and the ultrasonic transducers over time. Degasging the solution reduces the risk of cavitation erosion and prolongs the life of the equipment. Additionally, degasging the solution reduces the risk of foaming during the cleaning process, which can reduce cleaning efficiency and increase the risk of spillage.

Ultrasonic Cleaning Advantages and Disadvantages

Ultrasonic cleaning is a powerful and efficient method for removing dirt, grime, and other contaminants from a variety of surfaces. It utilises high-frequency sound waves to create microscopic bubbles in a cleaning solution that implode upon contact with the object being cleaned, providing a thorough and effective cleaning process. However, like any cleaning method, ultrasonic cleaning has its advantages and disadvantages.

Advantages of Ultrasonic Cleaning:

- Thorough Cleaning: Ultrasonic cleaning can clean even the most complex and hard-to-reach surfaces, such as blind holes, corners, and crevices. The microscopic bubbles created during the cleaning process penetrate into these areas, dislodging and removing contaminants.

- Time and Labour-Saving: Ultrasonic cleaning can clean many items in a relatively short amount of time. Additionally, it requires minimal labour, as the cleaning process is automated and can be monitored remotely.

- Non-Destructive: Ultrasonic cleaning is a gentle cleaning method that does not damage delicate surfaces. This makes it suitable for cleaning sensitive equipment and components such as electronic devices and precision parts.

- Environmentally Friendly: Ultrasonic cleaning requires less water and cleaning solution than other cleaning methods, making it more environmentally friendly. Additionally, the cleaning solutions used in ultrasonic cleaning are biodegradable, non-toxic, and non-flammable.

- Cost-Effective: Ultrasonic cleaning equipment is relatively affordable and requires minimal maintenance, making it a cost-effective cleaning method in the long run.

Disadvantages of Ultrasonic Cleaning:

- Potential Damage: While ultrasonic cleaning is generally safe for most materials, there is a risk of damage to certain surfaces, such as delicate coatings or soft plastics. Therefore, it is essential to select the right cleaning solution and frequency to prevent any potential damage.

- Safety Concerns: Ultrasonic cleaning uses high-frequency sound waves, which can be harmful to human health. It is important to ensure that the cleaning area is adequately ventilated and that the operator is wearing protective gear such as gloves, goggles, and ear protection.

- Limited Use on Large Items: Ultrasonic cleaning is not practical for cleaning large objects, as the equipment is typically designed for smaller items. Therefore, it may not be suitable for cleaning large parts or equipment.

- Limited Cleaning Solution Options: Ultrasonic cleaning requires a specific type of cleaning solution, which may not be suitable for all applications. For example, certain types of chemicals cannot be used in ultrasonic cleaning.

- Limited Efficacy on Certain Contaminants: While ultrasonic cleaning is an effective cleaning method for most contaminants, it may not be effective for certain types of contaminants such as heavy grease or carbon build-up.

What can you clean in an Ultrasonic Cleaner

Ultrasonic cleaning is a versatile and effective method for cleaning a wide range of objects and materials. It can be used to remove dirt, oil, grease, rust, and other contaminants from surfaces of different sizes, shapes, and materials.

Metal Parts: Ultrasonic cleaning is particularly effective for cleaning metal parts. It can remove oil, grease, rust, and other contaminants from metal surfaces, including small crevices and hard-to-reach areas. This makes it an ideal method for cleaning automotive and aerospace components, machine parts, and tools.

Electronic Components: Electronic components are often delicate and require specialised cleaning methods to avoid damage. Ultrasonic cleaning is a gentle and effective method for cleaning electronic components such as circuit boards, connectors, and sensors. It can remove flux, solder, and other contaminants without damaging the components.

Jewelry: Ultrasonic cleaning is a popular method for cleaning jewelry because it can remove dirt, grime, and other contaminants from small crevices and hard-to-reach areas. It can also remove tarnish from silver and gold jewelry without causing damage. However, caution must be taken when cleaning jewelry with gemstones, as some stones can be damaged by ultrasonic cleaning.

Medical Instruments: Ultrasonic cleaning is a critical method for cleaning medical instruments, including surgical tools and equipment. It can remove blood, tissue, and other biological materials from the surfaces of instruments, which can reduce the risk of infection and improve patient safety. It is also an effective method for cleaning dental instruments, such as drills and probes.

Optical Components: Optical components, such as lenses and prisms, are often delicate and require careful cleaning to avoid scratches or other damage. Ultrasonic cleaning can remove dirt, dust, and other contaminants from the surfaces of optical components without causing damage. However, caution must be taken when cleaning coated optics, as the coating can be damaged by ultrasonic cleaning.

Coins and Collectibles: Ultrasonic cleaning is a popular method for cleaning coins and other collectibles, as it can remove dirt, grime, and other contaminants without causing damage to the surface of the object. However, caution must be taken when cleaning coins and collectibles that have valuable patina or surface finishes, as ultrasonic cleaning can remove these finishes.