Ultrasonic Cleaner to remove Rust

Rust and corrosion are common problems in metal tools and components, which can cause damage and reduce the efficiency of the tool. Rust forms when the iron in the steel reacts with oxygen and moisture in the air. This chemical reaction causes the surface of the metal to corrode, forming a reddish-brown layer of iron oxide. Traditional cleaning methods such as manual scrubbing, sandblasting, and chemical treatments can be time-consuming and may cause damage to the tool's surface. Ultrasonic cleaning is an effective and efficient solution to remove rust and corrosion from metal tools, including moulding tools.

Will Ultrasonic Cleaning remove Rust

Ultrasonic cleaning has several benefits for removing rust from metal objects. First, it is a non-abrasive process that does not damage the surface of the metal. This is important, especially for delicate or intricate metal objects that cannot be cleaned using traditional methods. Second, ultrasonic cleaning is fast and efficient, making it ideal for cleaning large quantities of metal objects. Finally, ultrasonic cleaning is a safe and eco-friendly process that does not use harsh chemicals or produce toxic waste.

Removing Rust & Corrosion from Moulding Tool - Case Study

A customer recently approached us with a request to remove burn marks and rust from two moulding tools made of tool steel. The customer's criteria were to clean the tools thoroughly without damaging the surface or affecting the integrity of the tools. The moulding tools were contaminated with burn marks and rust, which can affect the tool's performance and lifespan. The tools needed to be cleaned without damaging the surface or affecting the integrity of the tools.

| Ultrasonic Cleaner | Cleaning Agent | Temperature(s) | Concentration |

|---|---|---|---|

| Kemet 12 Ultrasonic Cleaner | Solvit 4 | 40°C | 10% |

Process for cleaning mould tool

We recommended using an ultrasonic cleaner with Solvit 4 cleaning agent, which is specially formulated for removing rust and corrosion from metal tools. The ultrasonic cleaner used in this case study was the Kemet 12 Ultrasonic Cleaner, which is designed for industrial cleaning applications. The moulding tools were placed in the ultrasonic cleaner's basket and immersed in Solvit 4 cleaning agent at a concentration of 10%. The ultrasonic cleaner was heated to a temperature of 40°C, and the cleaning cycle was set for 10 minutes. During the cleaning cycle, the basket was manually dunked after 5 minutes to remove any loose debris from the surface of the tool. After the 10-minute cleaning cycle, the moulding tools were removed from the ultrasonic cleaner, rinsed with clean water, and dried with compressed air. The results were impressive, and both tools were free from rust and burn marks without any damage to the surface or integrity of the tools.

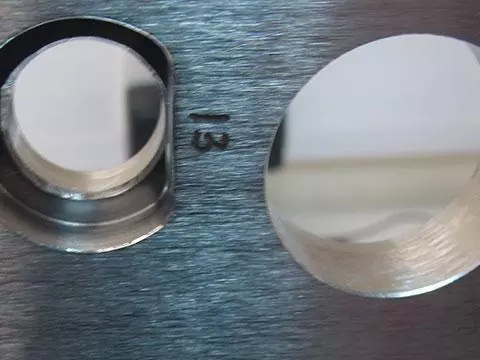

Before cleaning moulding tool

After cleaning moulding tool

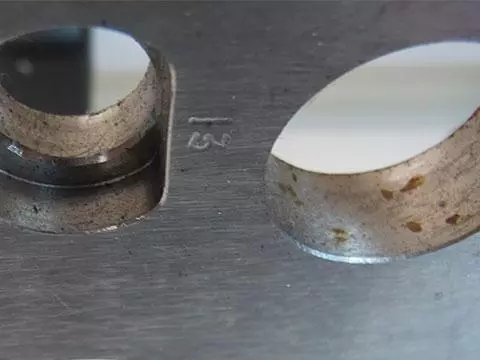

Customers Criteria: Free from all contamination

Component: Plastic injection moulds tools

Material: Tool Steel

Contamination prior to cleaning: Plastic injection residue, corrosion

| Ultrasonic Cleaner | Cleaning Agent | Temperature(s) | Concentration |

|---|---|---|---|

| Kemet 30 | Solvit 4 | 40°C | 10% |

| Kemet 30 | DI water + Korrostop 5000 | 50°C | 0.1% |

| Versa 120 Dryer | N/A | 65°C | 100% |

Quickest way to remove rust

Due to the moulds being heavily contaminated with corrosion an acidic product is required; Solvit 4 was used due to its high de-oxidizing and degreasing properties. All tanks were degassed for 10 minutes and allowed to reach the required temperature before cleaning. All tools had a total cleaning time of 20 minutes in the ultrasonic using the sweep mode to ensure a thorough clean. Next the tools were rinsed in deionised water with a 0.1% concentration of a corrosion additive Korrostop 5000. Korrostop 5000 is used to protect steel against corrosion and does not leave any film that could disturb the following operations. Next the tools were dried in a hot air dryer unit for 20 minutes at 70°C. Note: Increased concentration and process time may produce a better result.

Before removing rust

After removing rust

Customers Criteria: Remove all contamination

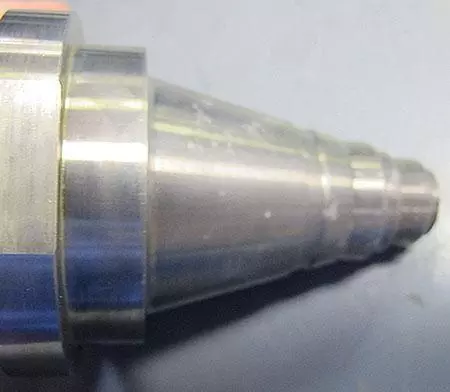

Component: Tool

Material: Tool Steel

Contamination prior to cleaning: Grease, dirt, burn marks & plastic extrusion

Number off per run: 1

| Ultrasonic Cleaner | Cleaning Agent | Temperature(s) | Concentration |

|---|---|---|---|

| Versa 120 | H14 | 50°C | 10% |

| Versa 120 | De-ionised water | 50°C | 100% |

| Versa 120 Dryer | N/A | 70°C | 5 minutes |

Process for removing grease, dirt, burn marks & plastic extrusion

The tool was placed into the basket and then submerged into the tank and set for a cycle time of 10 minutes. As soon as the Sonics are turned on you can see the contamination being removed. After the wash cycle the parts have to be rinsed to neutralize any left on cleaning agent and contamination. Finally the parts were dried in the Versa hot air dryer set at 70°C for 5 minutes.

% Satisfactorily Cleaned: 100%

Before cleaning

After cleaning