Lapping & Polishing Punch Dies - Case Studies

Test Requirements: To produce mirror finish on ground parts

Component/Material: 2 Punch dies

Machine Type: Kemet 15 lapping machine

Part A - A temporary fixture was made to hold the part and used during both lapping and polishing stages. The part was lapped for 10 minutes then inspected, all machine grinding marks had been removed and a uniform lapped finish remains. Next the part was thoroughly cleaned using CO42 cleaning fluid as to not contaminate the polishing stage. Finally the part was polished for 5 minutes.

Part B - This part was lapped and polished by hand as the required surface face is small, a fixture could be made which would allow you to lap and polish multiple parts automatically. Again this part was lapped for 5 minutes to remove all grinding marks, thoroughly cleaned then polished for 3 minutes.

Additional Info: The parts were cleaned using CO-42 cleaning fluid, If large number of parts require lapping/polishing, we would recommend using ultrasonic cleaning as this will reduce cleaning times with repeatable excellent results.

| Lapping Process breakdown for punch dies | |||

|---|---|---|---|

| Stage | Plate/cloth type | Abrasive type/grade | Process time |

| 1 Lap | Kemet Iron | Liquid diamond 14 Micron Type K standard | 10 minutes |

| 2 Polish | ASFL polishing pad | Liquid diamond 3 Micron Type K standard | 5 minutes |

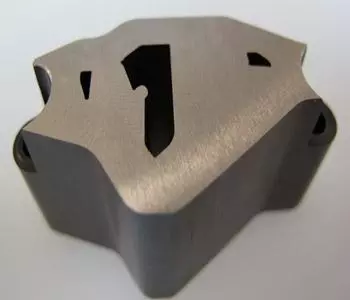

Before Lapping Punch Die

After Lapping Punch Die

Polishing Tablet Punches

Tablet punches are widely used by pharmaceutical companies. Kemet International has considerable experience at polishing tablet punches. The face of the tablet punch when new is normally very fine, good quality and spark eroded. To polish the tablet punch, the punch is normally rotated in a "lathe" type chuck. Hand Lapping sticks or power polishers are then used. If the tablet punch has raised letters or a pattern, then the initial work will have to be done with the punch held stationary. A suggested sequence to use is as follows:

- Hard wood lapping sticks with Kemet Diamond Compound 6-KD-C3 or Kemet Diamond Compound 6-W-C3 and a very small quantity of Kemet Lubricating fluid Type OS.

- Soft Wood Lapping Sticks using Kemet Diamond Compound 6-KD-C3 or Kemet Diamond Compound 6-W-C3.

- Final Polishing using Felt Bobs or Felt Cones (or brushes if the punch has raised / sunken letters or patterns) using Kemet Diamond Compound 1-KD-C3 or Kemet Diamond Compound 1-W-C3 and very small quantities of Kemet Lubricating fluid Type OS.

- After a production run, the punches normally require ultrasonic cleaning and re-polishing before storage with a protective lubricant.

Kemet offer a Tablet punch polishing kit (Kemet code, 321847). The kit includes a KFD rotary drive unit, 1 x Kemet Diamond Compound (6 Micron), Kemet Lubricating fluid Type OS plus various lapping sticks, felts and brushes.